ULTRAVIOLET (UV) LIGHT TREATMENT IN BREWERIES

Ultraviolet (UV) light for the Brewery Industry

Process water in contact with beer carries specific microbiological hazards, so it is critical to have the right water treatment strategy in place. Each production process includes specific microbiological hazards. In other words, each process should be protected against specific micro-organisms.

Traditionally, UV systems for the brewing industry are based on ‘general UV dose’ of 25 or 40 mJ/cm2. The experts at bestUV have a different approach. bestUV designs UV systems for the brewing industry that are based on the hazards specific to a stage of beer production.

In breweries, some micro-organisms can be killed with low UV doses. Others require high UV doses. So, the UV disinfection strategy is determined by the type of micro-organism (bacteria, moulds, yeasts), position of the UV treatment to the end-product (beer), and the function of the process water to treat.

The advantage of UV treatment is that is a chemical-free method, which does not change the taste, color, pH, minerals of the process water. No residuals are left in the treated water to get in contact with the end product.

BetaLine UV

BetaLine UV is a series of optimized “L-shaped” units. The inlet and outlet are positioned at 90°, providing predictable hydraulics while passing the UV lamps. Read More...

BetaLine-E UV

The BetaLine-E series uses unique high-efficient amalgam low-pressure UV lamps called Ecolight. The lamps emit germicidal wavelengths at 254nm. Read More...

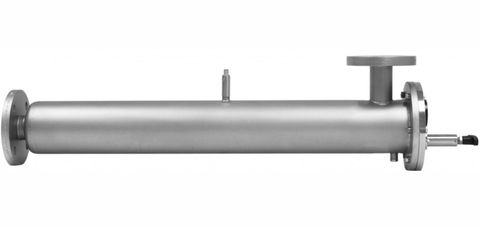

AlfaLine UV

AlfaLine UV, the most compact UV system, is designed for all types of water treatment. The systems prevent fouling of the quartz sleeves and UV sensor with an effective manual or electrical ‘anti-fouling mechanism’. Read More...

KappaLine UV

This unique combination of compactness and high efficiency makes it stand out as the only system available in the market that combines all the advantages of both medium- and low- pressure systems. Read More...