CONTINUOUS LEVEL MEASUREMENT FOR BREWERIES

Level Sensors for Continuous Level Measurement in the Brewery Industry

Continuous level sensors establish the level in tanks or vessels by using a step less method. The filling level is converted into an electrical signal for further processing. It can be displayed on location or used for process control. In addition to potentiometric filling a level sensor which measures the filling level in small vessels up to 3 m high, the hydrostatic measuring principle is employed in larger tanks or when measuring non-conductive media. The pressure sensors developed for this purpose are used for high precision measurement in continuous level sensors and for the exact determination of differential pressure.

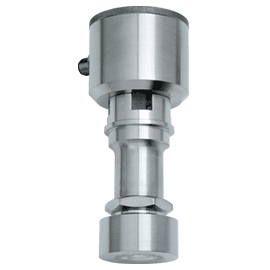

NSL-F

Level measurement in metallic tanks up to 140°C/284°F, straight and angled probe.

NSL-F-02

Level measurement in metal/plastic tanks up to 140°C/284°F, compact version – dual probe

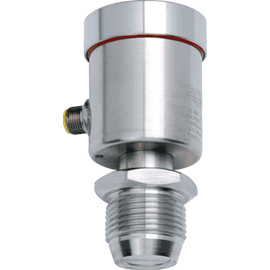

DAN-HH

Process pressure measurement, sensor with metallic diaphragm up to 150 °C/302°F

DAN-045, DAN-046, DAN-047, DAN-048, DAN-049

Process pressure measurement in small pipes and vessels