FLOW MEASUREMENT IN DAIRIES

Flow Measurement and Flow Control for hygienic application in the Dairy Industry

Anderson-Negele's flow meters (magnetic-inductive or turbine flow meters) and flow monitors (ultrasonic or calorimetric) are specifically designed for the use in hygienic applications. These flow meters and flow monitors meet the requirements from the Dairy industry in terms of accuracy, life span and cleaning.

Instek Control offers sensors from Anderson-Negele with two different measuring principles for flow monitoring:

- Ultrasonic Flow Monitor has an extremely rapid response time and works absolutely independent of temperature changes.

- Flow Monitor with Calorimetric Measuring Principle can be used to measure highly pure or ultra-filtered fluids.

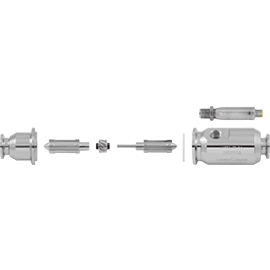

FWS-141, FWA-141

Flow monitoring in pipes from DN25 on of media with particles > 50 µm

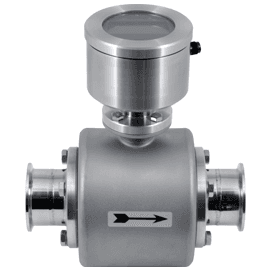

FMI

Flow & volume measurement of media with minimum conductivity >5 µs/cm; accuracy ±0.2% ± 1 mm

FMQ

Flow & volume measurement of media with minimum conductivity >5 µs/cm; accuracy ±0.5% ± 2 mm