BREWERY INSTRUMENTATION

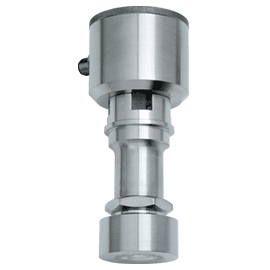

- Point Level Measurement

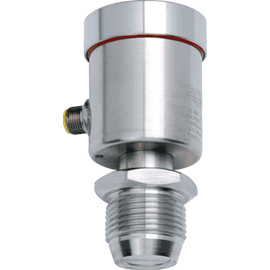

- Continuous Level Measurement

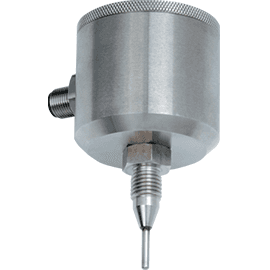

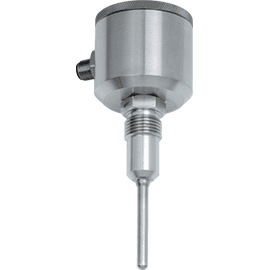

- Temperature Measurement

- Flow Measurement

- Pressure Measurement

- Proximity Sensors

- Hygienic Instrumentation

- Turbidity Measurement

- Conductivity Measurement

- Biofilm Measurement

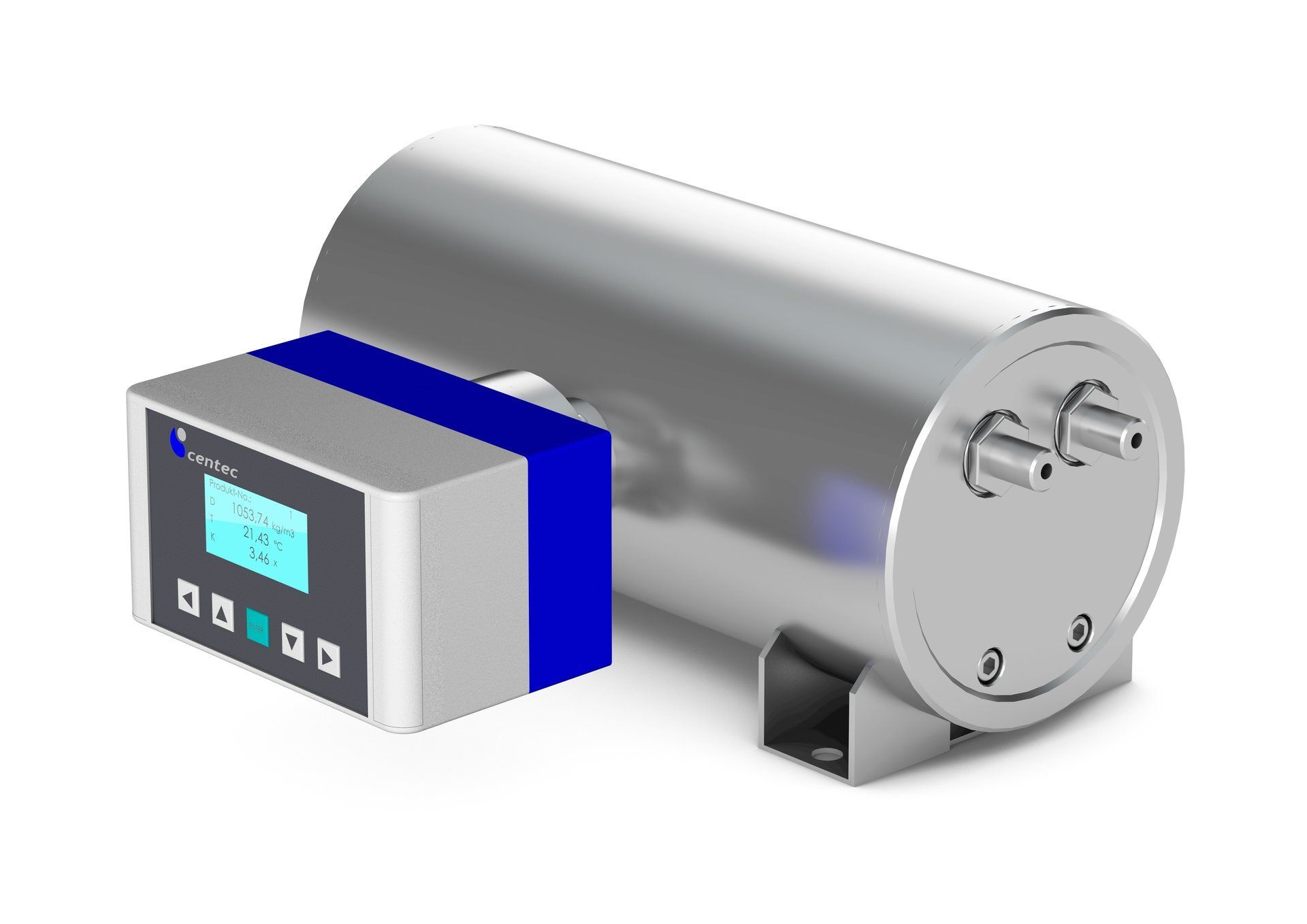

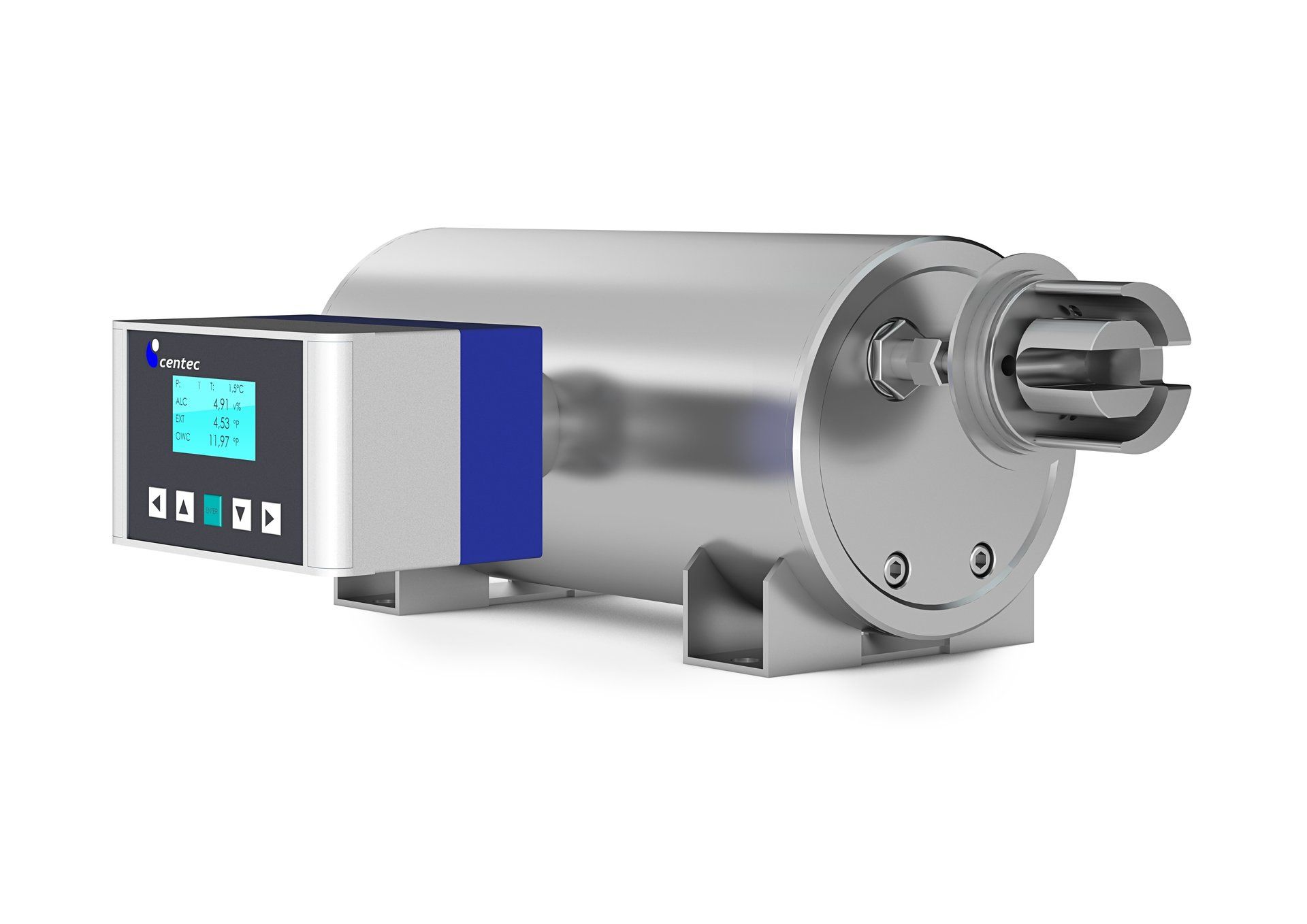

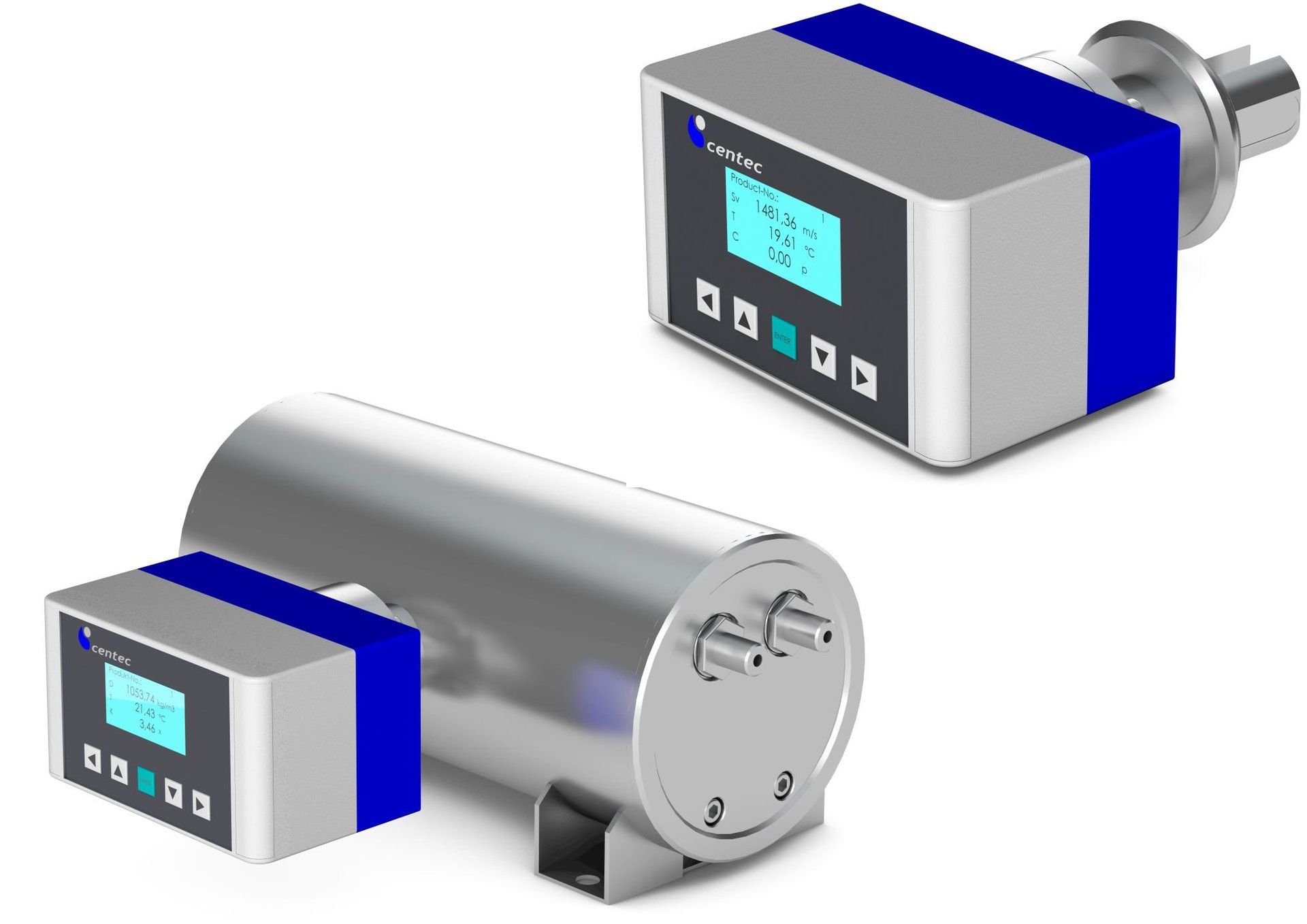

- Extract Measurement

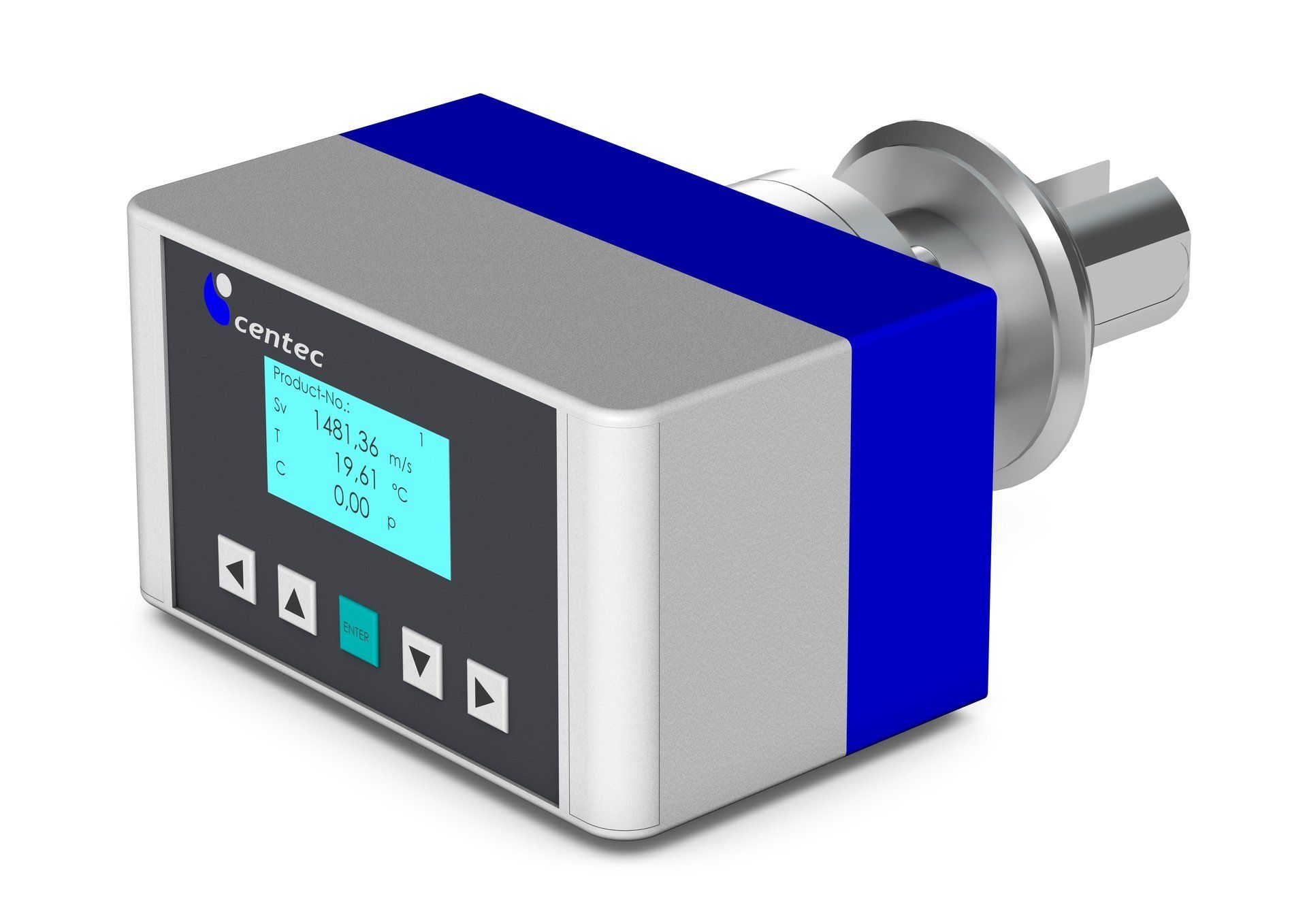

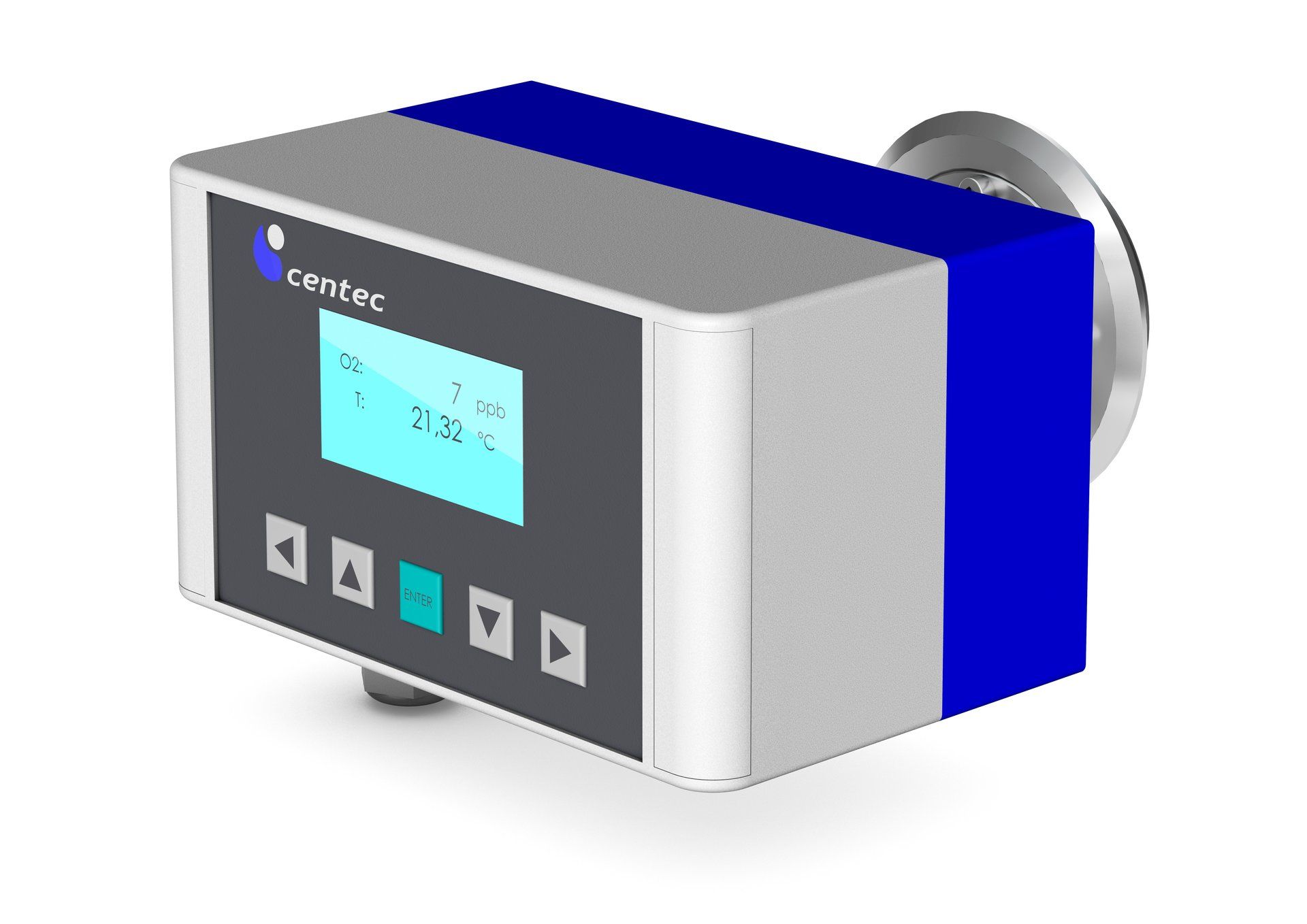

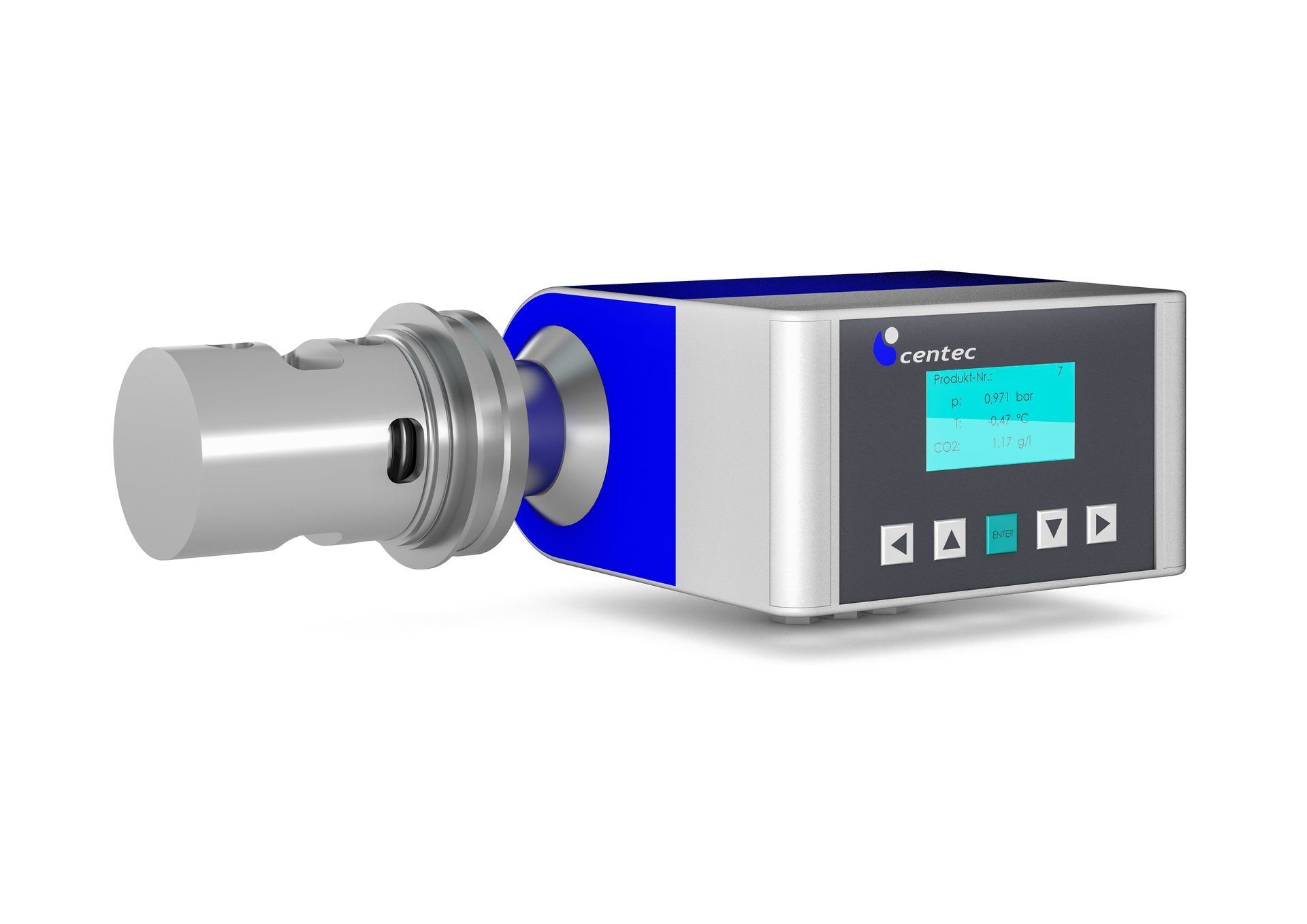

- O₂ and CO₂ Measurement

- Alcohol Measurement

- Plato Measurement

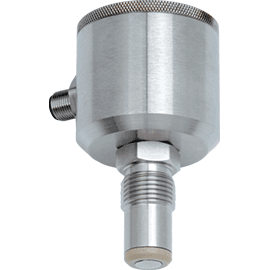

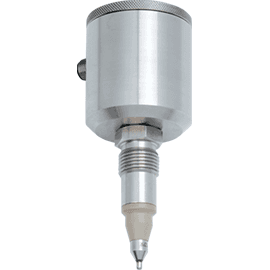

HYGIENIC LEVEL SENSORS FOR THE POINT LEVEL DETECTION IN BREWERY INDUSTRIES

Level Sensors for Point Level Detection in the Brewery Industry

CONTINUOUS LEVEL MEASUREMENT FOR BREWERIES

Level Sensors for Continuous Level Measurement in the Brewery Industry

TEMPERATURE MEASUREMENT

Temperature Sensors for Brewery Industries

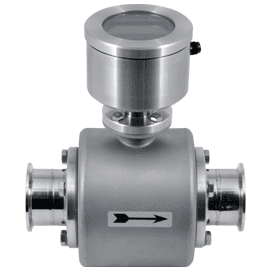

FLOW MEASUREMENT IN BREWERIES

Flow Measurement and Flow Control for hygienic application in the Brewery Industry

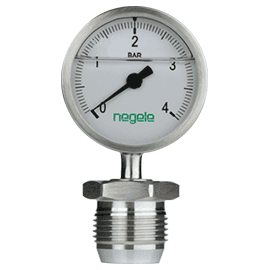

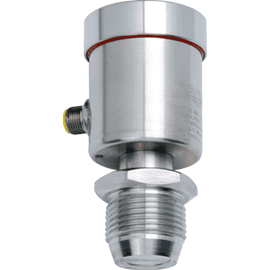

PRESSURE MEASUREMENT IN BREWERIES

Pressure Sensors & Gauges for the Brewery Industry

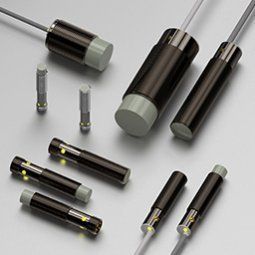

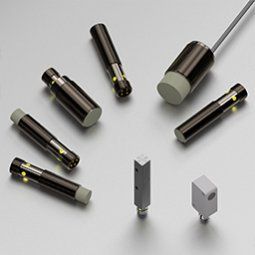

PROXIMITY SWITCHES FOR THE BREWERY INDUSTRY

CAPACITIVE PROXIMITY SWITCHES

Capacitive - Performance Metal Housings

High sensing distances are needed in some environments. Xecro's Capacitive Sensors offer best-in-class sensing distances. The manufactures shielded capacitive sensors such as e.g. M8 with 2 mm sensing distance, M12 with 6 mm sensing distance and M18 with 15 mm sensing distance. Unshielded Capacitive Performance Series in M30 housings, achieve up to a 35mm sensing distance.

In order to integrate the sensors into different environments, the diameters M12, M18 and M30 are provided with a build-in multi-turn potentiometer to adjust their sensitivity and adapt them to different application requirements. The potentiometer is also an optional extra for Ø6.5 and M8 sensors.

Capacitive - High Temperature

XECRO’s Capacitive - High Temperature Series sensors has been designed for use in permanent environmental temperatures ranging between -25…+150 °C (-13 … 302 °F). The electronics of the Capacitive – High Temperature Series sensors fit into the identical housing as other capacitive sensors from XECRO. These sensors are available in sizes ranging from M8 to M30 and are constructed with silicone or Teflon® (PTFE) cables. Silicone cable has an impressive flexibility which makes it a perfect choice for installations where the sensor permanently moves causing flex in the cable. Conversely, Teflon® has an excellent robustness and should be considered for installations where the sensor body is located on a stationary mount.

Capacitive - Flat Body

The extra thin CS3050 from XECRO is a great choice for installations on non-metal tanks and containers. The built-in potentiometer allows to adjust sensitivity until the device senses material through container walls.

Its flat design, only 7mm in height, eliminates the need for extra fixtures as by cylindrical sensors.

Capacitive - Cubic 40x40

This sensor offers best flexibility due to its rotatable sensing head which can be mounted in five directions. XECRO's sensors in this housing provide NO + NC outputs in the 10… 30 VDC version and in 2-wire for 20…250 VAC. The sensor electronics and the mounting sockets are two separate parts. This special construction simplifies the replacement procedure of a mechanically damaged sensing head.

The 40x40 sensors are available in industrial standard sensing distances and in XECROs High Performance sensing distances.

Capacitive - Ring Sensors

These sensors detect liquids or other high conductive material in tubes. This makes them an ideal choice for level sensing applications based on the principle of communicating pipes. Since the capacitive sensing principle does not support high switching frequencies, these capacitive ring sensors are only suitable for objects which remain static inside the inner ring. The circular design of the sensing electrode requires highly conductive material to function. Therefore wooden plugs or lime balls are no suitable targets.

Please contact

INSTEK CONTROL to get application related assistance.

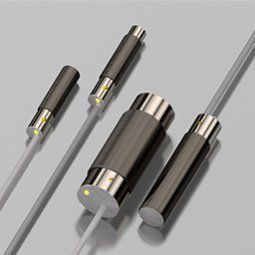

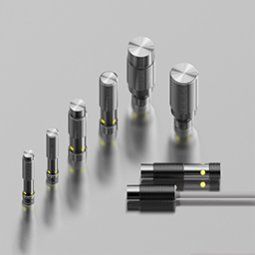

INDUCTIVE PROXIMITY SWITCHES

Inductive - High Performance

Extremely high sensing distances are required and essential for proper operation in some work environments. Sensors from the outstanding Performance Series offer the absolute best-in-class sensing distances.

M8 semi-shielded 4 mm down to 18 mm short

M12 semi-shielded 6 mm down to 22 mm short

M12 semi-shielded 8 mm down to 30 mm short

M18 semi-shielded 15 mm down to 35 mm short

M30 unshielded 50 mm down to 35 mm short

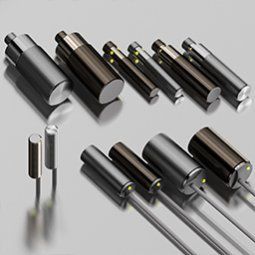

Inductive - Ultra Metal Face

These sensors are constructed with an ultra thick sensing face based on Ultra-Metal-Face technology. Made of stainless steel and designed to withstand the heaviest mechanical impacts. The advantage of these sensors is to enable application engineers to achieve perfect positioning precision. These sensors have been down-tuned to short sensing distances of 1 mm only - on ferrous and non-ferrous metal (Factor-1). The combination of unseen industry robustness and a precise switching point offers a completely totally new and unique solution. The possibilities are endless - just drop a metal part on it and it works… precisely!

Inductive - Metal Face

Inductive sensors utilizing Metal-Face Technology are constructed with housings made from one continuous piece of stainless steel which also includes the sensing face. This extra portion of robustness creates an ideal sensor for working in environments where even long sensing ranges cannot prevent mechanical sensor damage from taking place. The highly optimized electronics allow XECRO the ability to manufacture these robust and reliable sensors using very short housings, which allow for mounting in smaller locations.

Inductive - Miniature Smallest Housings

Very thin (Ø3mm) and very short (18mm). Engineers are often faced with a particular need for sensors that fit into small areas or spaces. The XECRO Inductive – Miniature Series, include self-contained sensors which range in size from Ø3 mm to M5 including square-sectional sensors of 5x5 mm. The Inductive –Miniature Series is guaranteed to be manufactured with built-in LED indicators, short-circuit-proof output drivers and reverse polarity protection.

Inductive - High Temperature

XECRO Inductive High-Temperature Series sensors have been designed to permanently These sensors are available in sizes from M8 to M30 and are equipped with silicone or Teflon® (PTFE) cables. Silicone cable have an impressive flexibility which makes it a perfect choice for installations where the sensor’s mounting location continuously moves. Conversely, Teflon® has an excellent robustness and should be considered only for permanent, non-motion related installations.

Inductive - High Pressure

Precise position sensing that operates under high pressure requires well-constructed sensors. XECRO fulfills these requirements with the wide range of High–Pressure Series sensors produced with two specialized technologies. These technologies result in a permanent pressure resistant level of up to 1000 bar +27 12 998 6326 psi). Sensors for pressures of up to 500 bar (7251 psi), utilize traditional ceramic sealing to separate both the ferrite/coil combination and the evaluation electronics from the pressure-facing section of the housing. To achieve outstanding pressure durability, XECRO manufactures select High–Pressure sensors with Metal-Face technology. This calls for the housing of the sensor to be constructed from one continuous piece of stainless steel, which also includes the sensing face. These full-metal constructions offer excellent peak-pressure immunity and survive even under the harshest environments. Most High – Pressure Series sensors from XECRO are available with a built-in LED indicator to simplify mechanical set-up.

Inductive - Weld Field Immune

Weld–Field Immune sensors are capable of operating even if exposed to the heaviest of magnetic fields typically seen when sensors are installed too close to industrial welding equipment. XECRO diversified the Weld–Field Immune Series into two different categories, more economical category, is supplied with brass housings and a PTFE front cap. The second, designed with Metal-Face technology, is for those environments where a high level of mechanical robustness and reliability is preferred or necessary.

Inductive - Analog Output

XECRO sensors with Analog – Output, are able to precisely measure distances to metal objects. They are ideal for position adjustment, distance measurement and metal classification / comparable applications. Analog current or voltage output is available in Extended sensing distances in sizes ranging from M8 to M30.

Inductive - Cubic 40x40

The 40x40 enclosure offers best flexibility due to its rotatable sensing head which can be mounted in five directions. XECRO's sensors in this housing provide NO + NC outputs in the 10… 30 VDC version and in 2-wire for 20…250 VAC. The sensor electronics and the mounting sockets are two separate parts. This special construction simplifies the replacement procedure of a mechanically damaged sensing head. These sensors are available in industrial standard sensing distances and in XECROs High Performance sensing distances.

Inductive - Ring Sensors

Inductive ring-sensors from XECRO can be used to detect metal objects at high velocity. With a maximum object speed of up to 45 m/s (147 ft/s), it allows the use of objects that are shot with compressed air. These sensors are available with static working principle that also allows their use as a wire detector. Static detection means that the switching output remains active as long as an object is in the inner ring - making the sensors a perfect choice for jam or wire break detection.

Please contact

INSTEK CONTROL to get application related assistance.

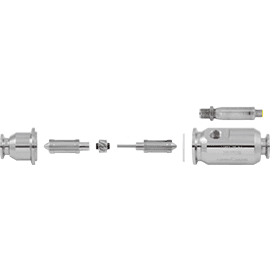

HYGIENIC INSTRUMENTATION FOR BREWERIES

Adapters and Fittings for hygienic applications in Breweries

CONDUCTIVITY MEASUREMENT IN THE BREWERY INDUSTRY

Inductive Conductivity Sensor for the Brewery Industry

TURBIDITY MEASUREMENT IN BREWERIES

Turbidity Sensors for the Brewery Industry

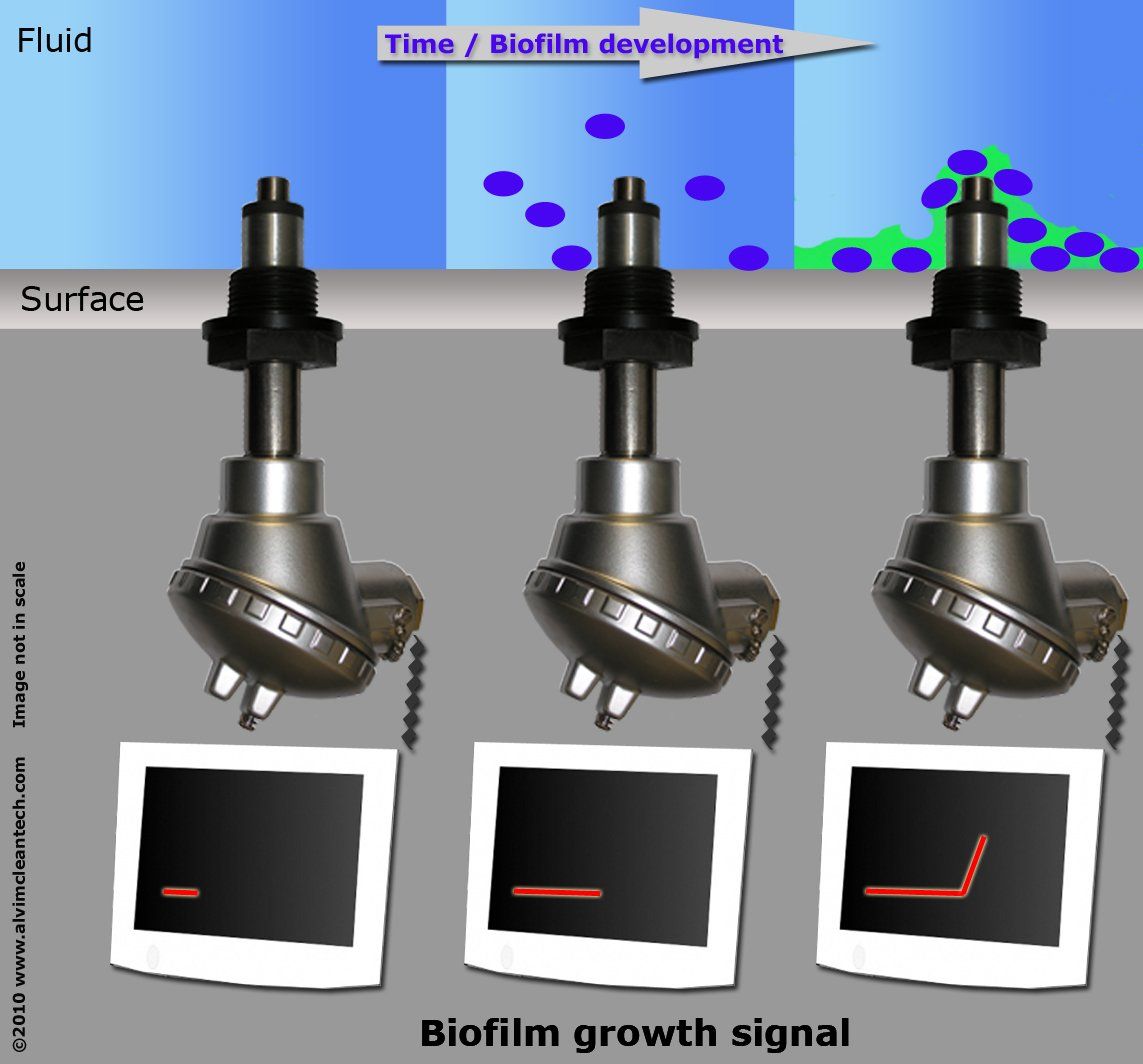

BIOFILM MONITORING

ALVIM Biofilm Monitoring System

What is bio film?

Important advantages of the ALVIM technology compared to other sensors in the market

- discriminates between biofilm and other kinds of deposit/fouling (e.g. calcium carbonate, etc.); this is extremely important, since these two different kinds of fouling requires different treatments;

- has a very high sensitivity, i.e. detects biofilm initial colonization phase; indeed, many biofilm related problems, such as Microbiologically Influenced Corrosion (MIC), start as soon as the first bacterial spots appear on a surface.

- Early-warning detection of bacterial biofilm growth by measuring the natural electrochemical activity of bacterial biofilm, indicating its real presence and extent in a given moment.

- Optimization of cleaning treatments (biocides, disinfectans, ...)

- Easy to install, easy to operate

- Virtually maintenance-free probe

- Real-time, continuous biofilm monitoring