CO₂ AND O₂ MEASUREMENT FOR BREWERIES

CO₂ AND O₂ Measurement for the Brewery Industry

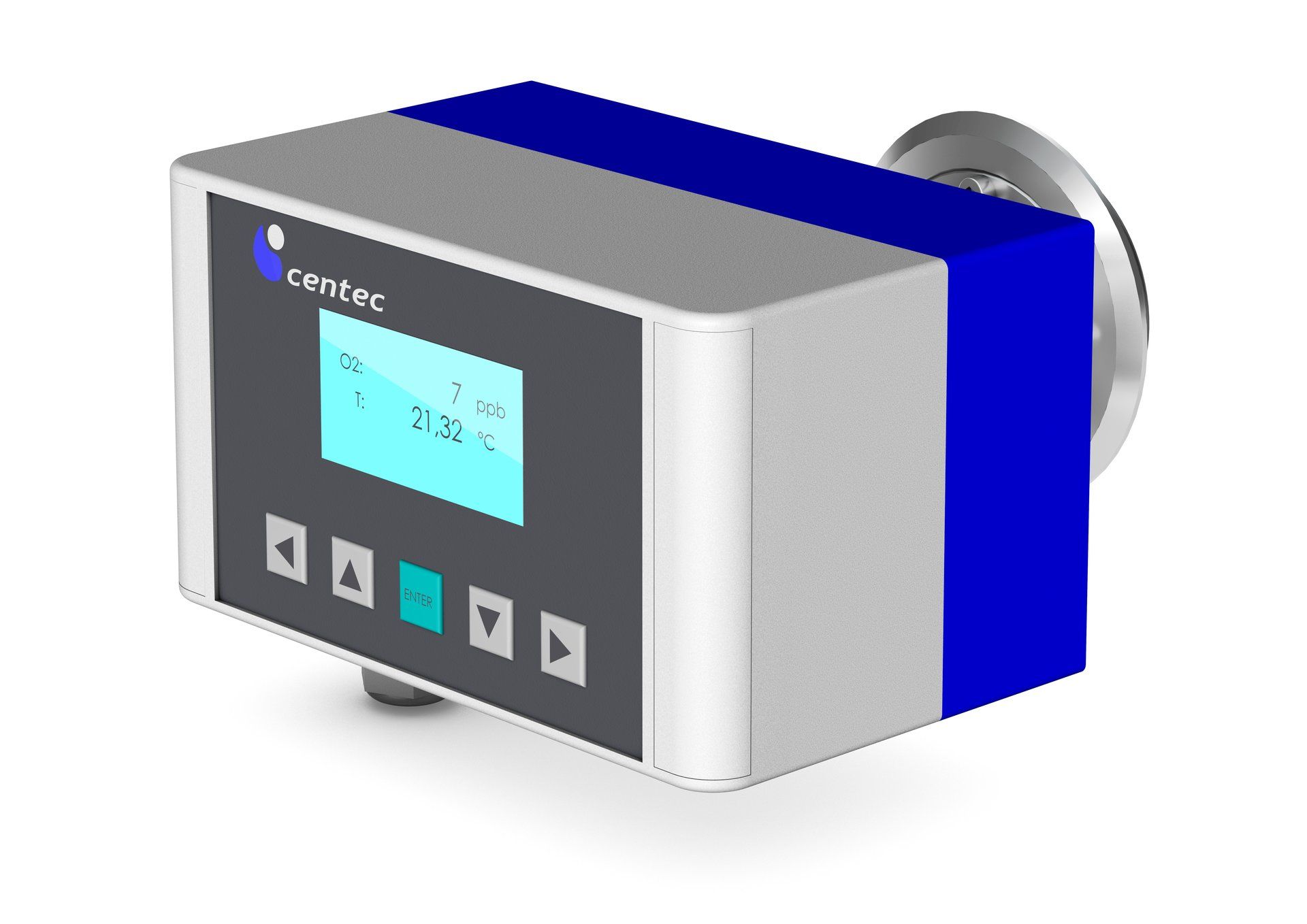

For continuous measurement of dissolved oxygen in liquids and gases, OXYTRANS is perfectly suited. The instrument is designed for applications requiring maximum sensitivity and highest accuracy. It is easy to operate and virtually maintenance-free. Electrolyte solutions are not necessary and no oxygen is consumed during the measurement. The optical measurement technology is based on the effect of luminescence quenching, i. e. the radiationless redistribution of excitation energy via molecular interaction.

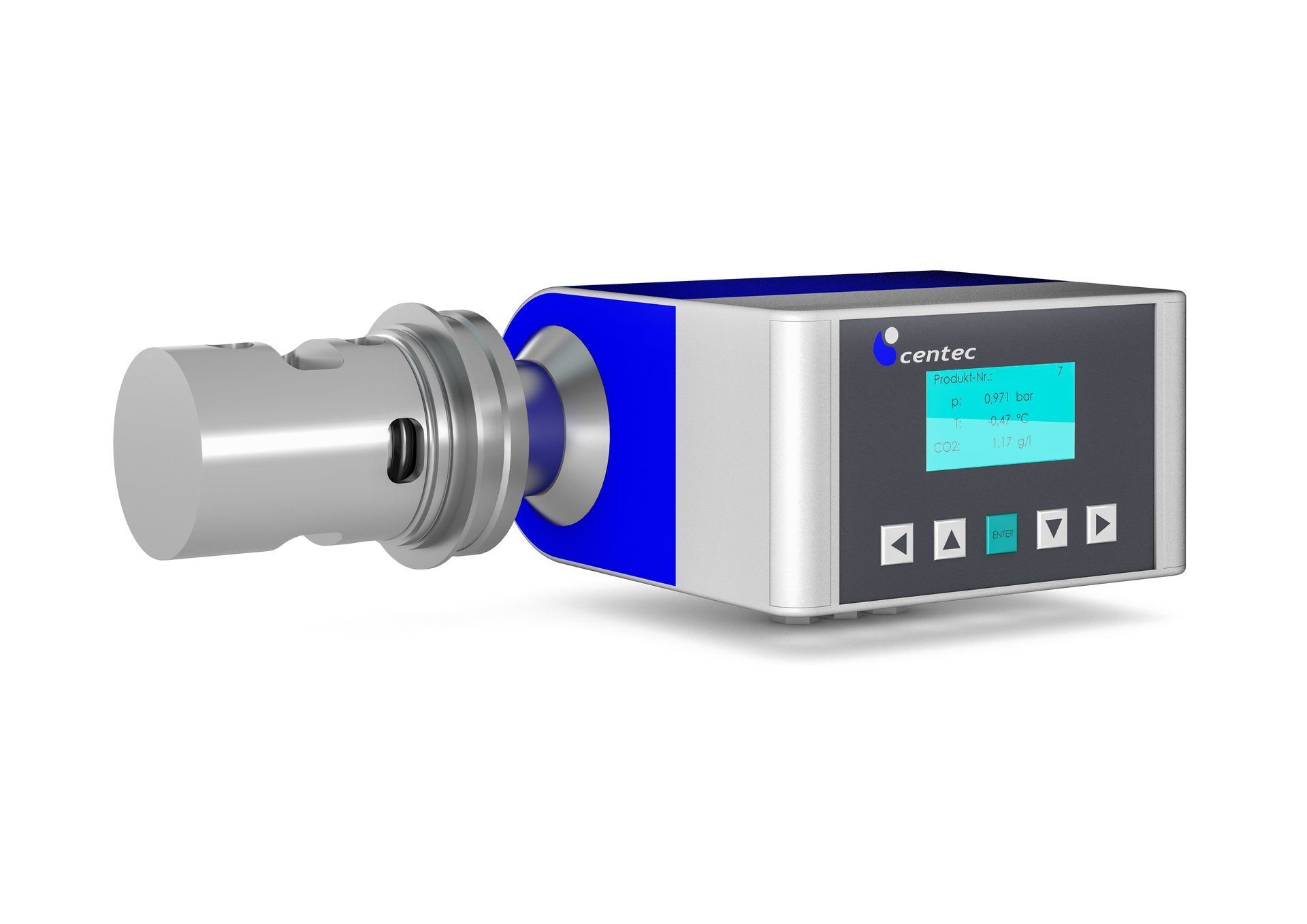

For continuous measurement of dissolved carbon dioxide in liquids, CARBOTEC TR-PT and CARBOTEC NIR is perfectly suited. For measuring carbon dioxide, the carbonated liquid flows through the sensor head (measurement chamber). everal times per minute the chamber is closed and its volume rapidly increases. This expansion generates a gas phase in the chamber. The large partial pressure difference of CO₂ forces the carbon dioxide out of the sample (liquid in the chamber) into the gas phase.

The new generation of CARBOTEC NIR sensors is based on Attenuated Total Reflection (ATR) technology. Near infrared (NIR) light is transmitted through a sapphire crystal.

CONDUCTIVITY MEASUREMENT IN THE BREWERY INDUSTRY

Inductive Conductivity Sensor for the Brewery Industry

The cost-effective ILM-4 conductivity meter is used for hygienic applications in brewing industries.

ILM-4 Inductive Conductivity Meter, utilized for the control of CIP processes (e.g. phase separation of detergent/water), concentration measurement (e.g. increasing the concentration of CIP detergents), can also be used for product monitoring and quality assurance. Remote Version NOW available.

TURBIDITY MEASUREMENT IN BREWERIES

Turbidity Sensors for the Brewery Industry

Turbidity Sensors - Reliable and Cost-Effective. The measurement of turbidity is an essential parameter for the automation of process runs in process engineering. INSTEK CONTROL, Anderson-Negele's distributor in South Africa and Sub-Saharan countries, offer sensors with different measuring methods for almost every customer application. The ITM-4 is perfectly suited for fresh water control in the beverage industry.

NITROGENATION FOR BREWERIES

Nitrogenerator – Nitrogenation for the Brewery Industry

For product nitrogenation the Nitrogenator has a specifically designed Vortex-Venturi injector that feeds nitrogen in a very large number of very fine bubbles directly into the product stream. Due to high pressure and turbulent flow, the N2 dissolves completely and absolutely homogeneously in a very short time. At the end of the dissolving path a control valve is installed. This valve keeps the pressure in the system constant and above the saturation pressure. The system is equipped with high precision flow meters. Based on the measurement of the flows, the product steam and the nitrogen flow are instantly and fully automatically adjusted. Optionally, the N2 content of the nitrogenated product can be monitored by a nitrogen sensor. This sensor can be used for process control in addition to the ratio control. The desired concentration of N2 is precisely met in the nitrogenated product. The Nitrogenator is integrated into the CIP cleaning cycle of the main product line.

BIOFILM MONITORING

ALVIM Biofilm Monitoring System

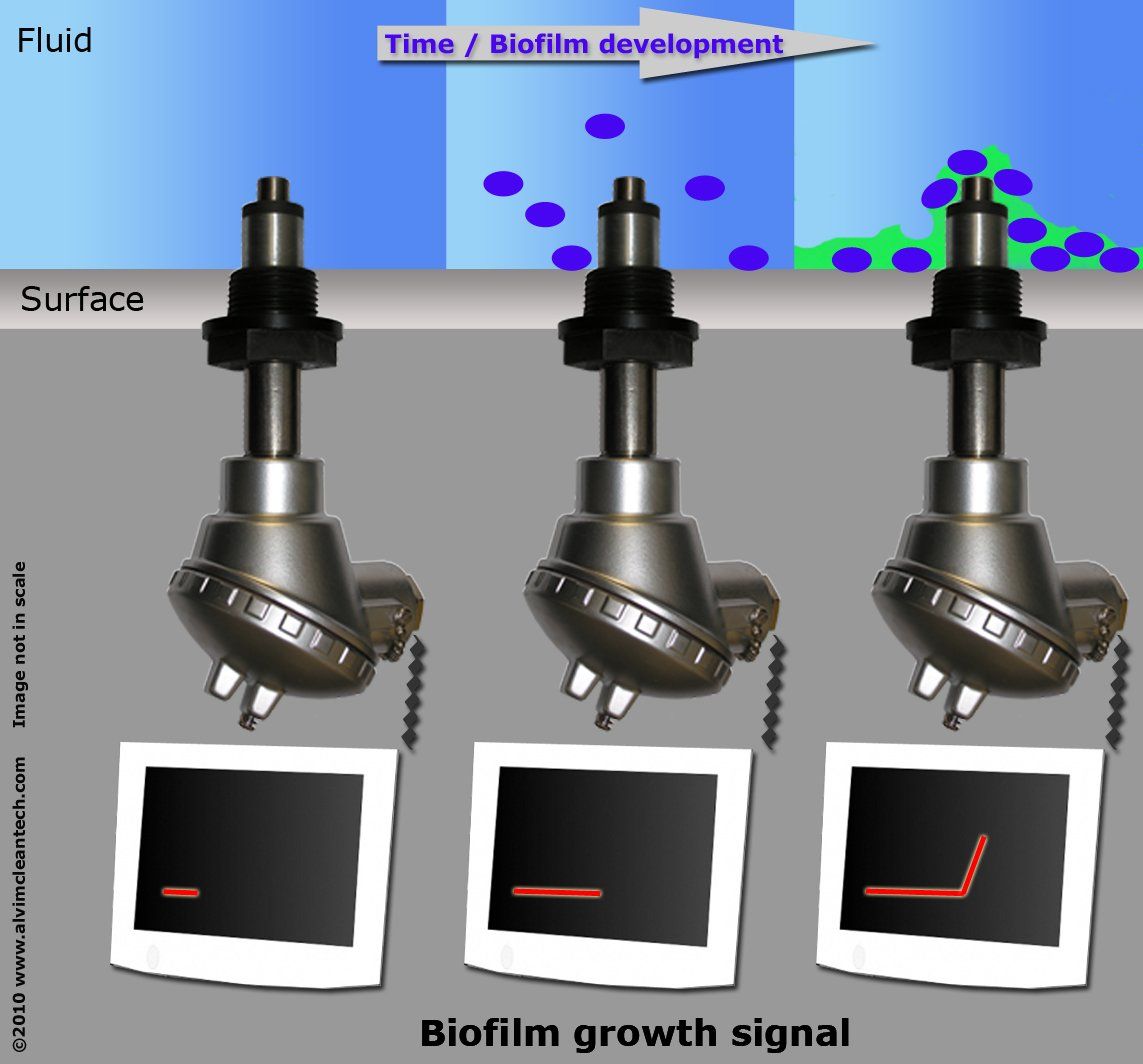

Bacteria settle among any structure (pipelines, tanks, machinery) in contact with the water in a very short time, if appropriate preventative measurements are not applied. The ALVIM real-time, on line, Biofilm Monitoring System is able to detect bacterial settlement since its first phases (down to 1% of surface covered by micro-organisms such as Legionella pneumophila) and, based on these data, manually or automatically adjust and optimize cleaning treatments / biocide treatments. This way keeping biofilm growth under control.

What is biofilm?

The terms biofilm refers to the layer of micro-organisms (bacteria, diatoms, fungi, etc.) that grows on any surface in contact with water or other liquids. It has been demonstrated that biofilm can grow even in extreme conditions, causing damages that can range from Legionella contamination to Microbiologically Influenced Corrosion (MIC).

Important advantages of the ALVIM technology compared to other sensors in the market

- discriminates between biofilm and other kinds of deposit/fouling (e.g. calcium carbonate, etc.); this is extremely important, since these two different kinds of fouling requires different treatments;

- has a very high sensitivity, i.e. detects biofilm initial colonization phase; indeed, many biofilm related problems, such as Microbiologically Influenced Corrosion (MIC), start as soon as the first bacterial spots appear on a surface.

- Early-warning detection of bacterial biofilm growth by measuring the natural electrochemical activity of bacterial biofilm, indicating its real presence and extent in a given moment.

- Optimization of cleaning treatments (biocides, disinfectans, ...)

- Easy to install, easy to operate

- Virtually maintenance-free probe

- Real-time, continuous biofilm monitoring

ALVIM Biofilm Sensor & Technical Datasheets

RECOVERY OF BEER FROM YEAST FOR BREWERIES

Yeast Recycler – Recovery of Beer from yeast for the Brewery Industry

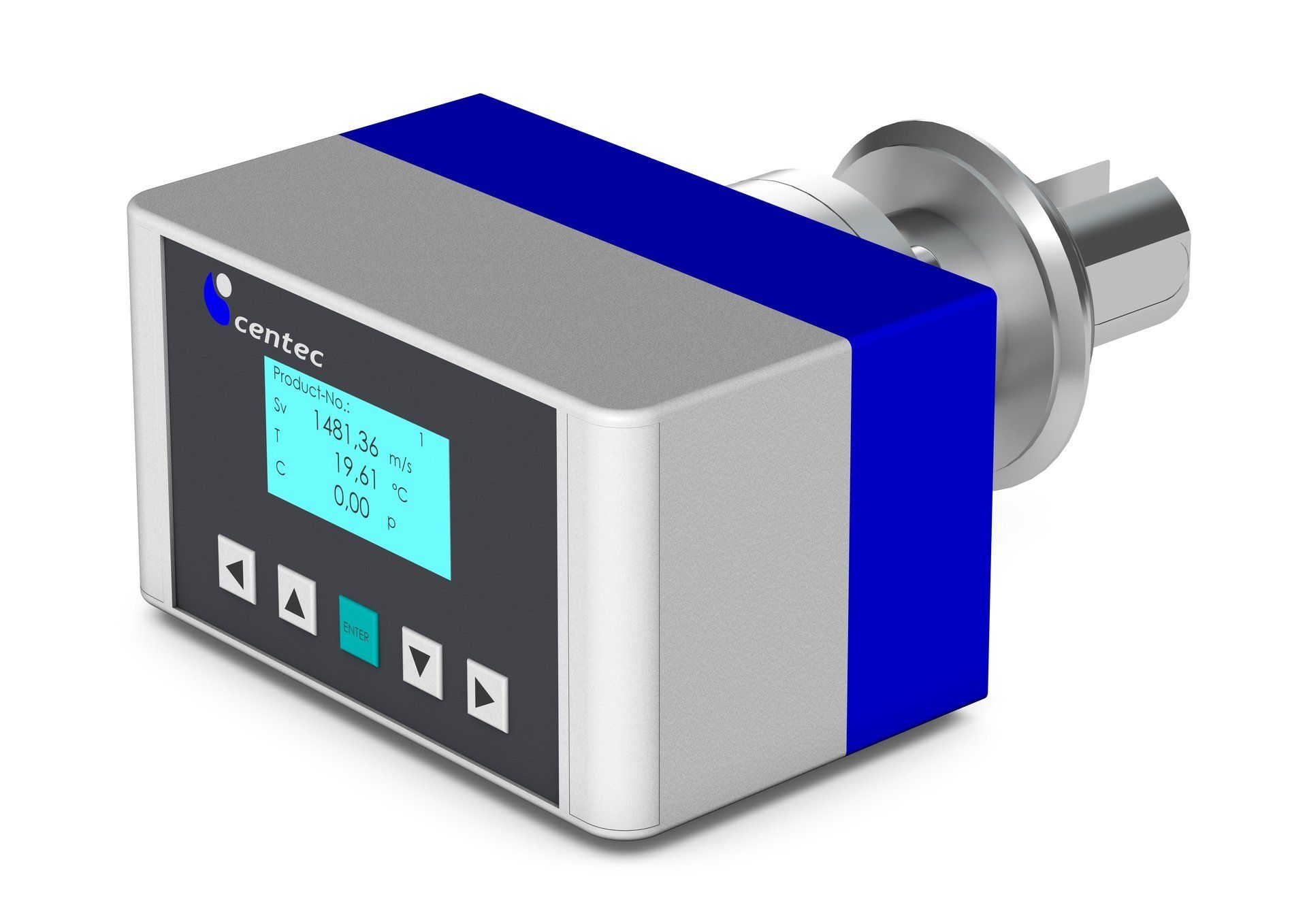

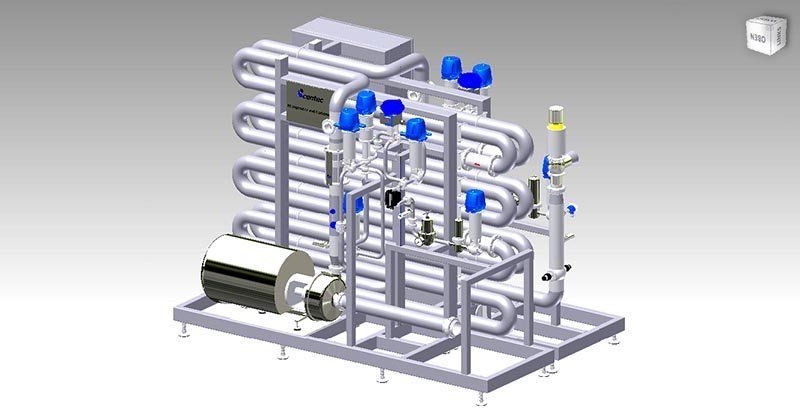

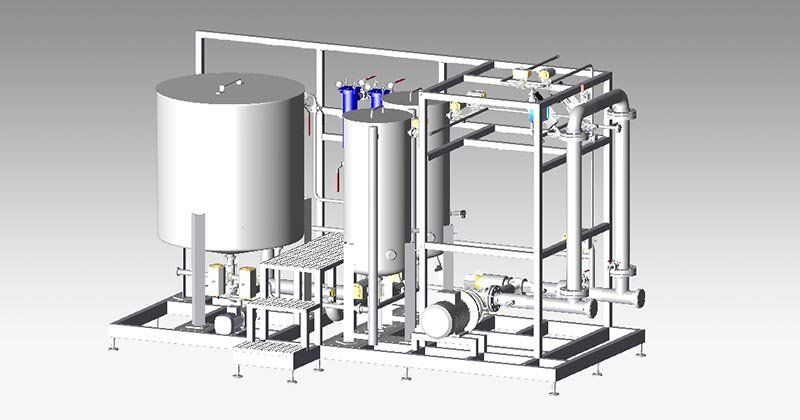

For beer recovery with the Yeast Recycler well proven cross-flow technology with robust ceramic membranes is used. The modular design is applicable for all brewery sizes. The recovered filtrate is free of yeast and takes up a minimum of oxygen. Recovered beer can be blended back into the brewing process at a ratio of up to 5 % without negatively influencing the quality of the final product. By adding small amounts of water to the waste yeast, beer recovery is optimized by a wash out effect (diafiltration). The advantage of diafiltration is a higher recovery rate. The O2 content can be monitored by high precision optical OXYTRANS sensors made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for O2 control. The Yeast Recycler is highly standardized resulting in low capital costs, a short amortization period and fast pay-back. Furthermore, it can easily be expanded by adding other Centec systems, e. g. for water deaeration and for blending.

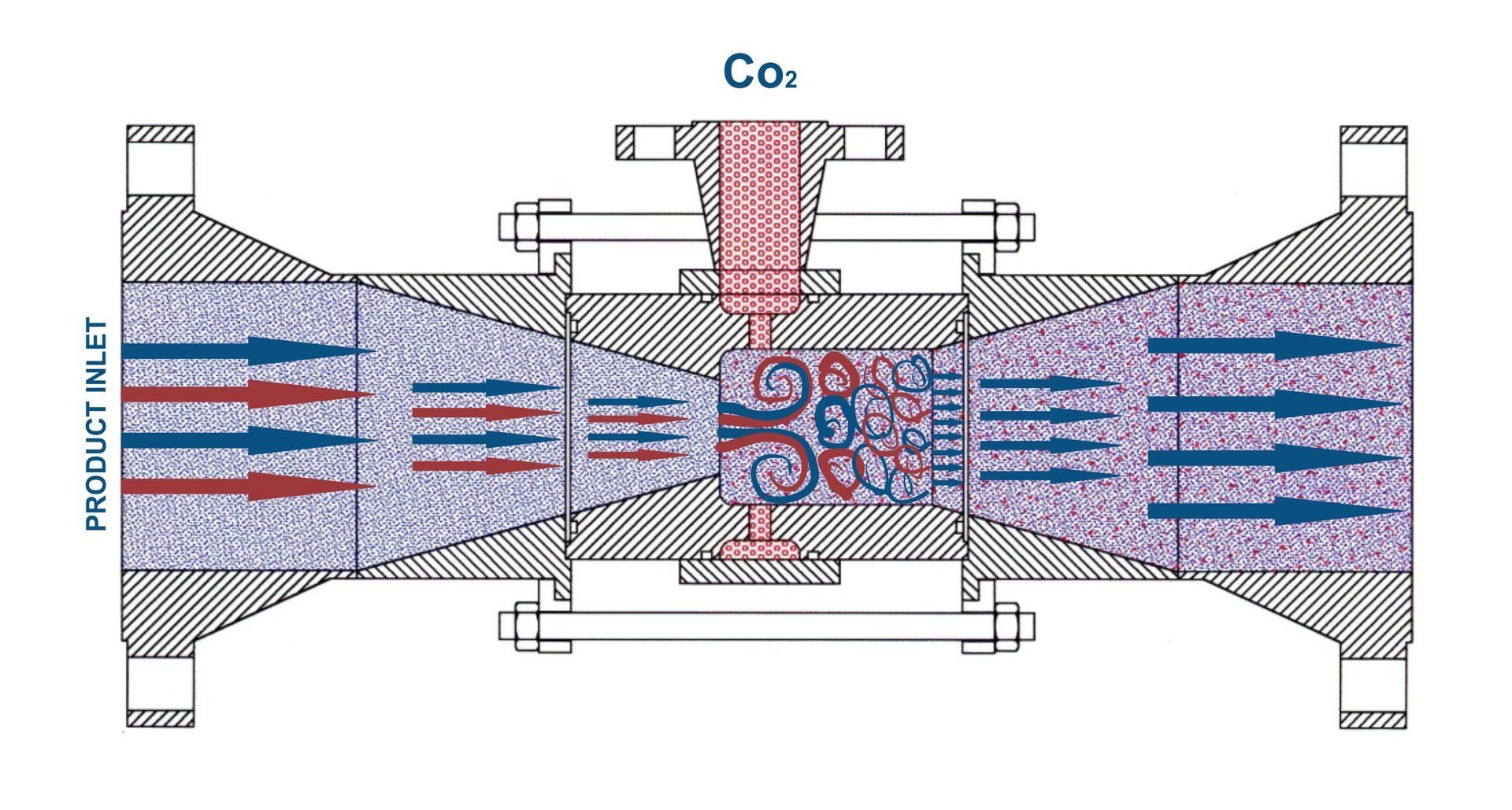

CENTEC VORTEX INJECTOR

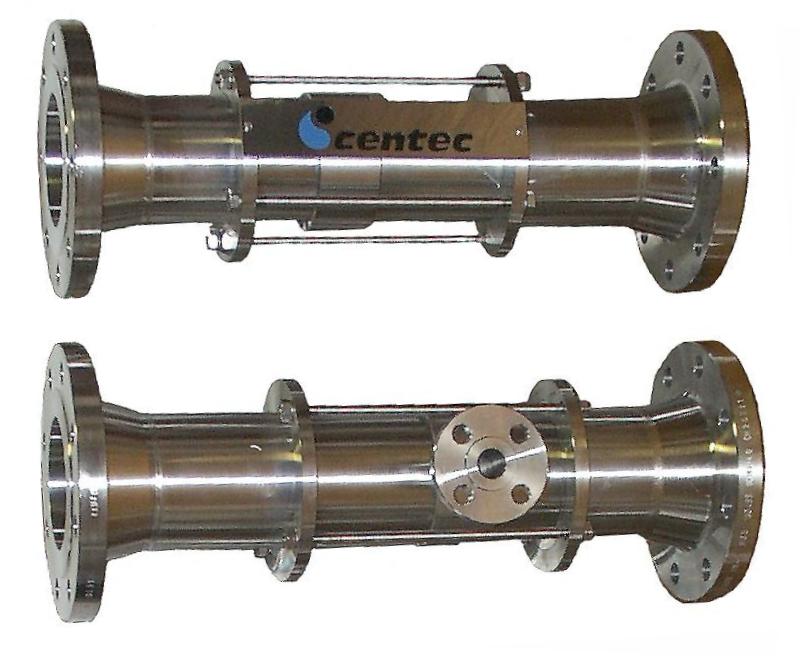

Homogeneous mixing of Gas, e.g. CO2 , O2 or N2, with liquids or beverages.

The Centec Vortex injector is a hydrodynamic nozzle for the injection and dispersion of gases into liquids. There is a large number of applications that require e.g. O₂, CO₂ or N₂ to be quickly and homogeneously added to beverages, wort, water or other types of cold or hot liquids. To always achieve optimal results, each Vortex injector is specifically designed according to the application duty and the products involved. Due to the design of the nozzle, the liquid is accelerated to reach a critical velocity before it enters the swirl chamber. Inside this chamber the gas is injected perpendicular to the product flow – sometimes from several directions. Due to high turbulence in the swirl chamber, the fine gas bubbles mix quickly and homogeneously with the product. The efficiency of the Vortex technology minimizes the size of the Carbonation units e.g. for adding pressurized carbon dioxide to beer, soft drinks and sparkling water. For instant and automatic adjustment of the gas flow, each skid can be designed to include a process control system, a dosing control valve and a highly reliable CARBOTEC or OXYTRANS sensor installed at the outlet, to monitor the product and to provide control feedback.