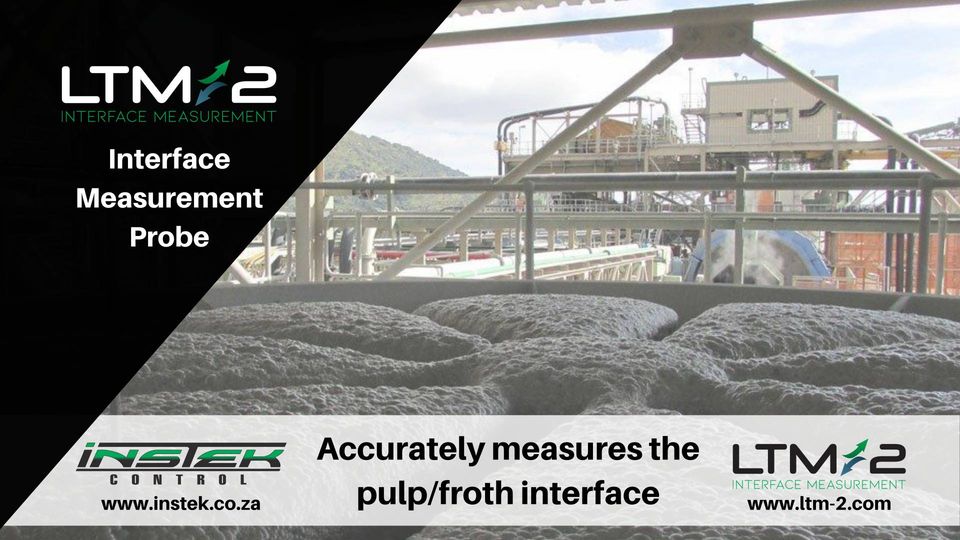

Easy 5-Minute Installation of the LTM-2

Simple and fast installation

One of the major benefits of the LTM-2 has proven to be its easy installation process.

Installing the LTM-2 probe instead of ultrasonic equipment has the advantage of not being density dependent and is not sensitive to froth or product build-up. The probe can be installed within five minutes and requires low maintenance, thereby making it “virtually maintenance free” as there are no mechanical moving parts. When installed and utilised correctly, the LTM-2 probe will deliver on performance, creating a stable control environment for flotation applications.

A benchmark success

With setup that can be achieved in less than 5 minutes, the LTM-2 probe has been adopted with great success, especially in the mining industry. Besides easy installation, the LTM-2 provides the following advantages when installed in place of ultrasonic devices:

- No moving parts

- Not density dependent

- Not sensitive to froth or product build-up

- The probes are virtually maintenance free

The unit has proven to accurately measures the pulp/froth interface and provides a stable feedback signal at an optimal update rate without excessive ‘damping’, all of which provides improved process control and stability.

Setting higher standards leads to continuous improvement of performance.

For more information, contact Instek Control.