Salute Giovanni Venturi!

In this blog post we are going back in time to toast the life of Italian physicist Giovanni Battista Venturi (1764 – 1822). He was responsible for figuring out an important element in basic fluid and airflow dynamics, which came to be known as The Venturi Effect.

Simply put, the Venturi effect shows that when a fluid is forced through a pipe that has a smaller cross-section, the static pressure and flow velocity increases. When the fluid then moves into a pipe with a larger cross – section, there will be an immediate pressure drop, creating a vacuum. The decrease in flow velocity creates high turbulence.

The Venturi effect is applicable to a range of disciplines ranging from Aeronautics to Agriculture, and everything in between. In the industrial and scientific fields, Venturi tubes are often used to measure the flow rate of a fluid.

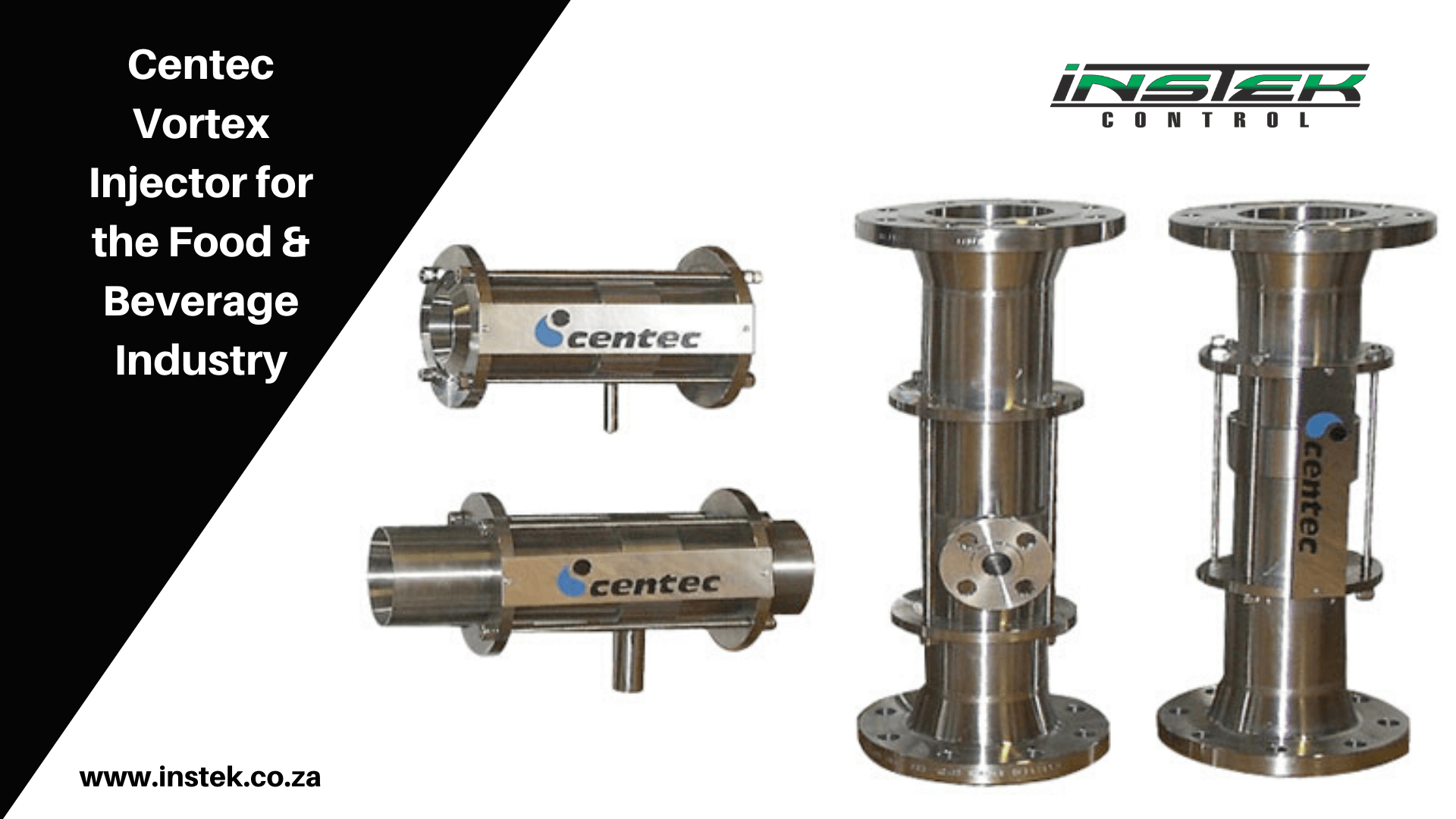

CO2 Injector for Food and Beverage Applications

Arguably, no one knows more about brewing beer than the Germans, therefore it is no surprise that 40-year old German company Centec GmbH, have used the Venturi principle to create what is known as the “best mixing system for carbonation and mixing of liquids to date.” Prosit Centec.

For the Food and Beverage Industry, Centec developed the Vortex Injector using the Venturi principle

The Centec Vortex Injector is especially designed for the homogeneous mixing of liquids and gas (e.g. CO2, O2 or N2) with beer, wine, or other beverages. Because this system is so effective the dissolving times are greatly reduced, and dosing can be done effectively, precisely and accurately.

Moving through the mixing chamber there is an immediate pressure drop that opens the liquid and creates a vacuum. This creates conditions for a near perfect fusion of liquids and or gases. The gas or liquid is injected into the product through multiple nozzles around the circumference of the mixing chamber. The homogenous mixing of the products take place instantaneously

this greatly reduces the size of a carbonation unit and adding carbon dioxide quickly and uniformly into beer, wine, beverages and sparkling water.

Best in the Business

The benefits of the Venturi Vortex Injector are numerous and include:

- Instant, homogenous mixing and additive dosing of liquids and gasses

- Application-specific design with the unique characteristics of each product and process incorporated

- Full CIP Capability

- Outstanding price-to-performance ratio

- Smaller holding loops and dissolving times resulting in more compact plant designs

- More accurate dosing ability resulting in material and time savings.

Contact Instek Control to discuss your specific high accuracy measuring and controlling needs when it comes to critical properties during food and beverage manufacturing, including oxygen, carbon dioxide, gravity and concentration.