INSTEK CONTROL CELEBRATES 10th ANNIVERSARY

Thank you for being part of our company's success over the years. We greatly appreciate and value your support, loyalty and dedication.

INSTEK CONTROL cc is celebrating 10 Years in the Import and Distribution of Quality Process Instrumentation. Looking back and reflecting on 10 years, we at INSTEK CONTROL would like to take this opportunity to thank all our loyal customers for their support and loyalty to the brand that has become synonymous with high quality reliable Instrumentation and Processing systems.

Starting out with an Exclusive Distribution agreement with Negele Messtechnik GmbH in 2007, and a dream, INSTEK CONTROL have gone through growth phases, ultimately becoming the dynamic and exciting entity it is currently.

Negele Messtechnik was a start to a much larger picture. After a Merger with Anderson Instrument Company, the trading name of Negele Messtechnik was changed to Anderson-Negele.

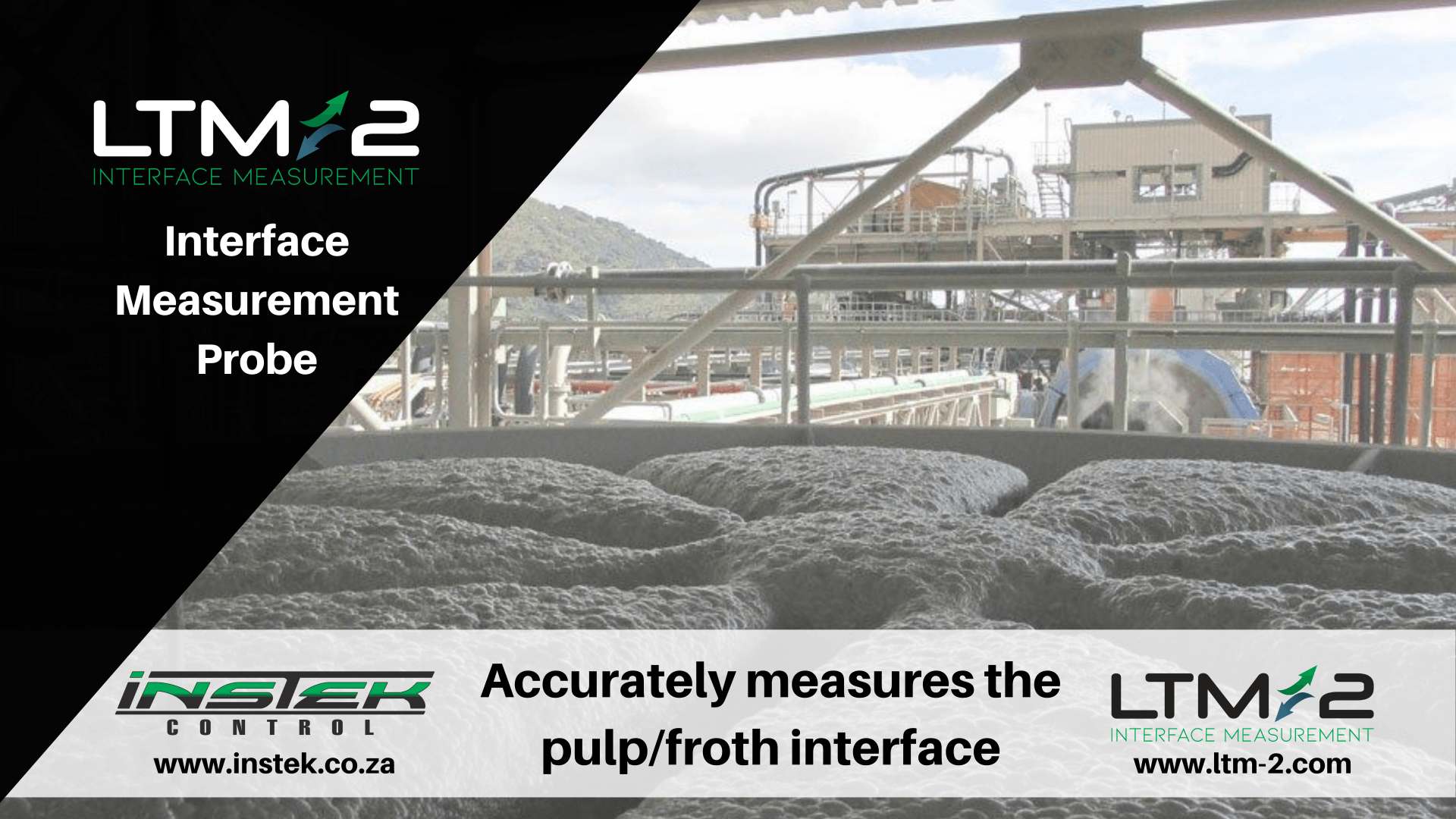

INSTEK CONTROL cc acquired the rights in 2010 to be the sole worldwide distributor for the LTM-2 level probe used for level measurement in the mining and related industries. Raymond Karsten the Managing Member of INSTEK CONTROL cc identified a niche application for this instrument and together with Anderson-Negele adapted this level probe specifically for applications in the mining and related industries to provide accurate level measurement in various difficult and sometimes seemingly impossible-to-measure applications. Typical applications include, but are not limited to, flotation banks, individual flotation cells, concentrate and other sumps.

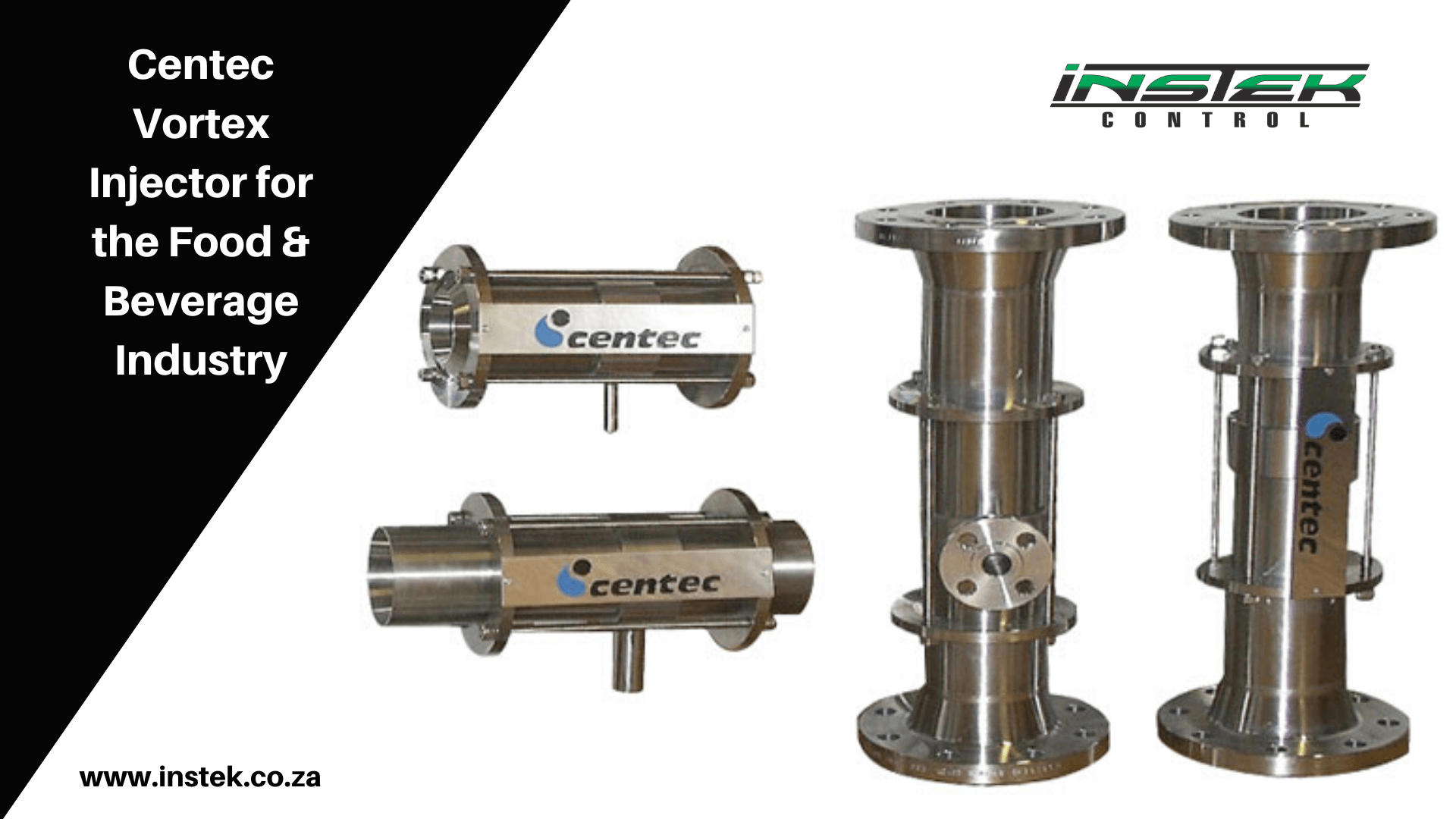

In 2013 INSTEK CONTROL was awarded Distributorship for Centec GmbH, supplying De-Aeration Plants, Multi Component Mixing systems, Aerators and various other items to the Brewing and Soft Drink Industry.

Xecro, a German manufacturer of Inductive Proximity Sensors, Panel Push Buttons and Capacitive Sensors, Werne & Thiel products for Dry Bulk moisture measurement, also became part of the product portfolio.

In 2015 Alvim BioFilm sensor for the measurement of Biofouling in Pipes joined the portfolio.

In 2017 bestUV, a Dutch manufacturer of UV lamps for Water treatment became part of the Product offering.

With this complete Portfolio, we feel that we can offer you, the customer, the solution you need in your Hygienic Processes to ensure that your product quality is always of the Highest Standards.

We thank you for making this dream become a reality and look forward to another decade of exciting business and growth.