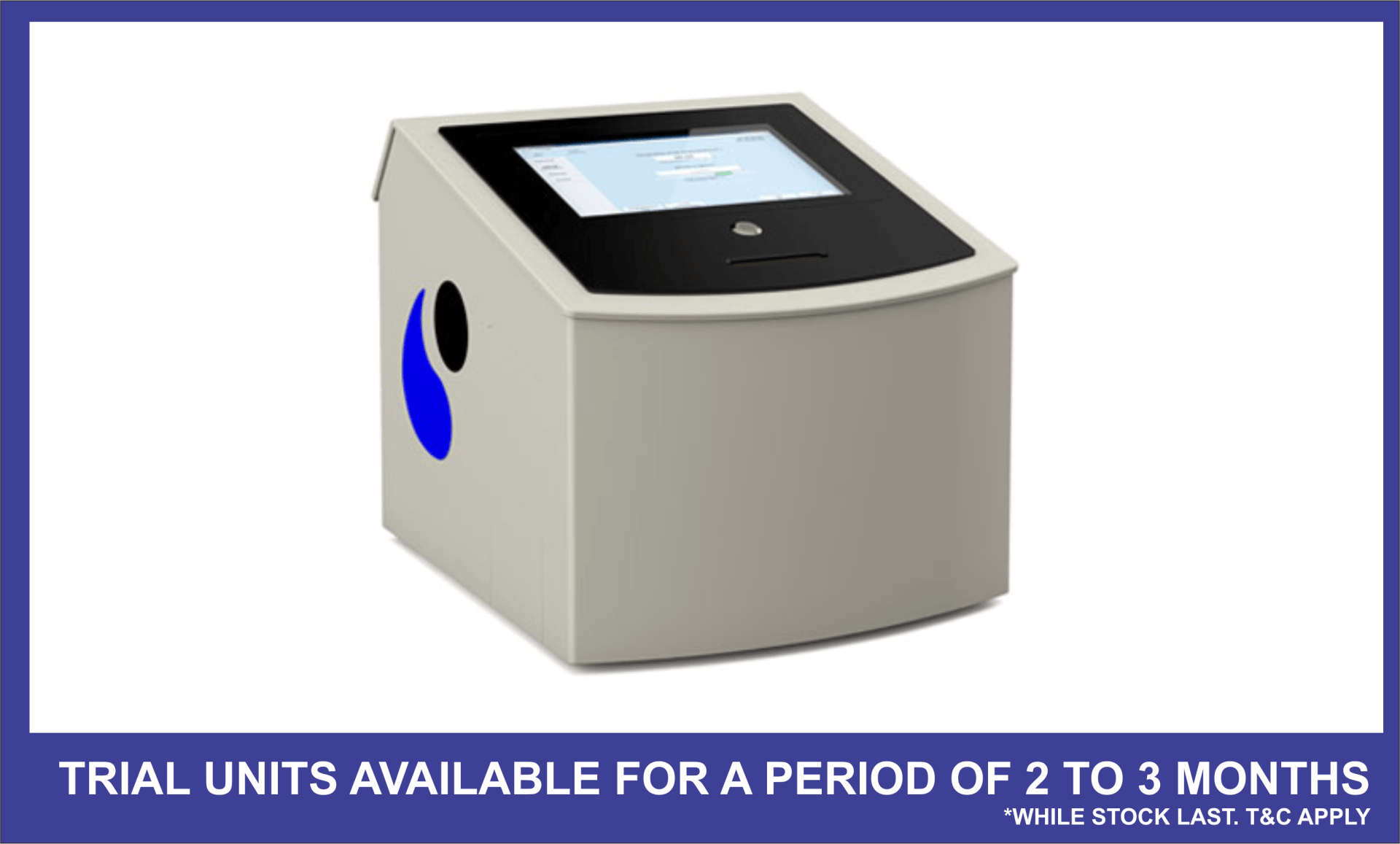

The newest version of RHOTEC L

With RHOTEC L you can measure the density and concentration in the lab with highest accuracy.

RHOTEC L is a highly precise density sensor for determination of densities and concentrations in the (e. g. of extract, alcohol, sugar, acids, caustics and solvents).

Description

The density sensor RHOTEC L measures the density of small liquid samples. They are manually injected into the sensor. The instrument is designed for laboratory applications requiring maximum sensitivity and highest accuracy. It is easy to operate and maintenance-free. Even the smallest changes in fluid density are identified with highest precision. Any temperature drifts of the measured signal are automatically compensated for by an internal Pt1000 sensor. RHOTEC L can display liquid density and solution concentration in various units (vol.%, mass%,°Brix and°Plato).

- Most accurate technology to determine density and concentration

- Software compatible with MS Windows® and MS Office®

- Various interfaces (USB, WLAN, Ethernet)

- User-friendly 10” touchscreen available

- Excellent price-performance-ratio

Technical Data

| Measuring Range | 0 - 3 g/cm3 |

| Accuracy | ± 0,0001 g/cm3 (higher on request) |

| Repeatability | ± 0,00005 g/cm3 (higher on request) |

| Repeatability Temperature | ± 0,02 °C |

| Sample Volume | approx. 2 ml |

| Measurement Time | 30 - 60 s |

| Temperature of Operation | +5 - + 85 °C |

| Temperature of Environment | +10 - + 40 °C |

| Temperature Sensor | Pt1000 |

| Material | glass, PTFE |

| Connections | nozzles, PTFE |

| Display | 10“ touchscreen |

| Interface | USB; WLAN; Ethernet |

| Housing | aluminum, powder coated |

| Weight | 22 kg |

| Power Supply | 230 VAC |

Contact Instek Control for more information.

Email: Info@instek.co.za /+27 (0) 12 998 6326