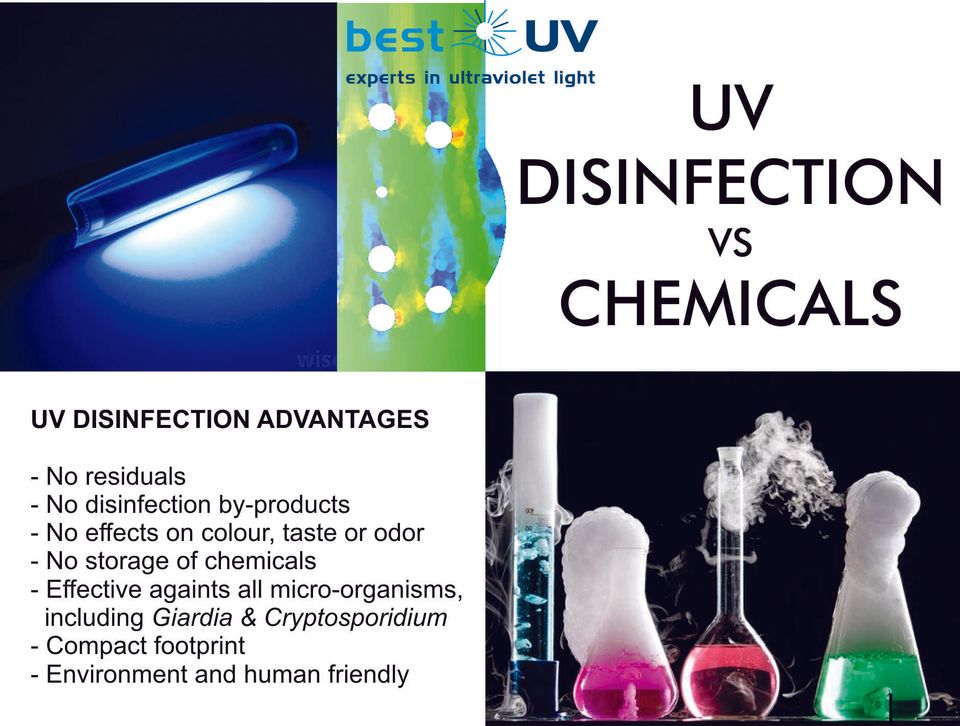

UV vs Chemicals

The major advantages of ultraviolet light versus chemicals: no residuals, no disinfection by-products, no effects on color, taste, odor, no storage of chemicals, effective against all microorganisms, including Giardia and Cryptosporidium, compact footprint, environment and human friendly

Ultraviolet light

Ultraviolet (UV) light is a natural part of sunlight; the short wavelengths are absorbed by the protecting ozone layer. UV lamps designed for water disinfection use a gas mixture containing the element mercury (Hg) vapour to produce ultraviolet light.

Mercury is an advantageous gas for UV disinfection applications because it emits light in the germicidal (‘germs killing’) wavelength range (UVC and UVB). The light output depends on the concentration of mercury atoms, which is directly related to the mercury vapor pressure.

Mercury at low vapour pressure produces essentially monochromatic (single wavelength) UV light at 253,7 nm, so-called low-pressure UV lamps.

At higher vapour pressures, the frequency of collisions between mercury atoms increases, producing UV light over a broad spectrum. These so-called polychromatic (more wavelengths) medium-pressure lamps have an overall higher intensity.

Exposure to UV light in the wavelength spectrum of 200 – 400 nm damages the genetic (DNA and RNA) and other molecules inside a micro-organism. The damage ‘kills’ the specific micro-organism.

Bacteria, protozoa, viruses, fungi, algae are all sensitive to UV light. Because of differences in their shape, they are sensitive to different wavelengths.

Applying UV light does not leave residuals in the water, which is an advantage over chemical disinfection methods. UV is proven to be very effective in inactivation of Giardia and Cryptosporidium with a very low dose.

Chlorination

The use of chlorine as a disinfectant is commonly accepted worldwide. People are becoming more concerned about the by-products of chlorine as it reacts with other organic compounds producing various compounds like e.g. trihalomethanes (THMs). THMs are documented as probable or possible human carcinogens.

Other disadvantages of chlorination are how it changes of taste and odours, the need for additional equipment such as tanks to guarantee proper contact time, and necessary monitoring to ensure proper concentration levels.

Chlorination is known to provide poor disinfection performance against viruses such as enterovirus and hepatitis A and microorganims such as Giardia and Cryptosporidium .

Ozonation

Ozone, one of the strongest oxidants known, is effective as an oxidising agent in reducing bacteria with a relatively short exposure time. Ozone generators are used to produce ozone gas on-site since the gas is unstable and has a very short life.

These systems must be carefully installed and monitored because high levels of ozone will oxidise and deteriorate all downstream piping and components. High levels of ozone are extremely harmful, especially in enclosed or low ventilation areas.

Furthermore ozone forms highly carcinogenic by-products at high bromide levels such as bromate, bromoform, dibromeacetic acid etc. This is becoming an even bigger concern with drinking water disinfection.

As a result of by-product formation some countries have already banned ozone for drinking water treatment.

For more information contact Instek Control +27 12 998 6326 or email raymond@instek.co.za