Good, better, best... Never let it rest. Til your good is better and your better is best...

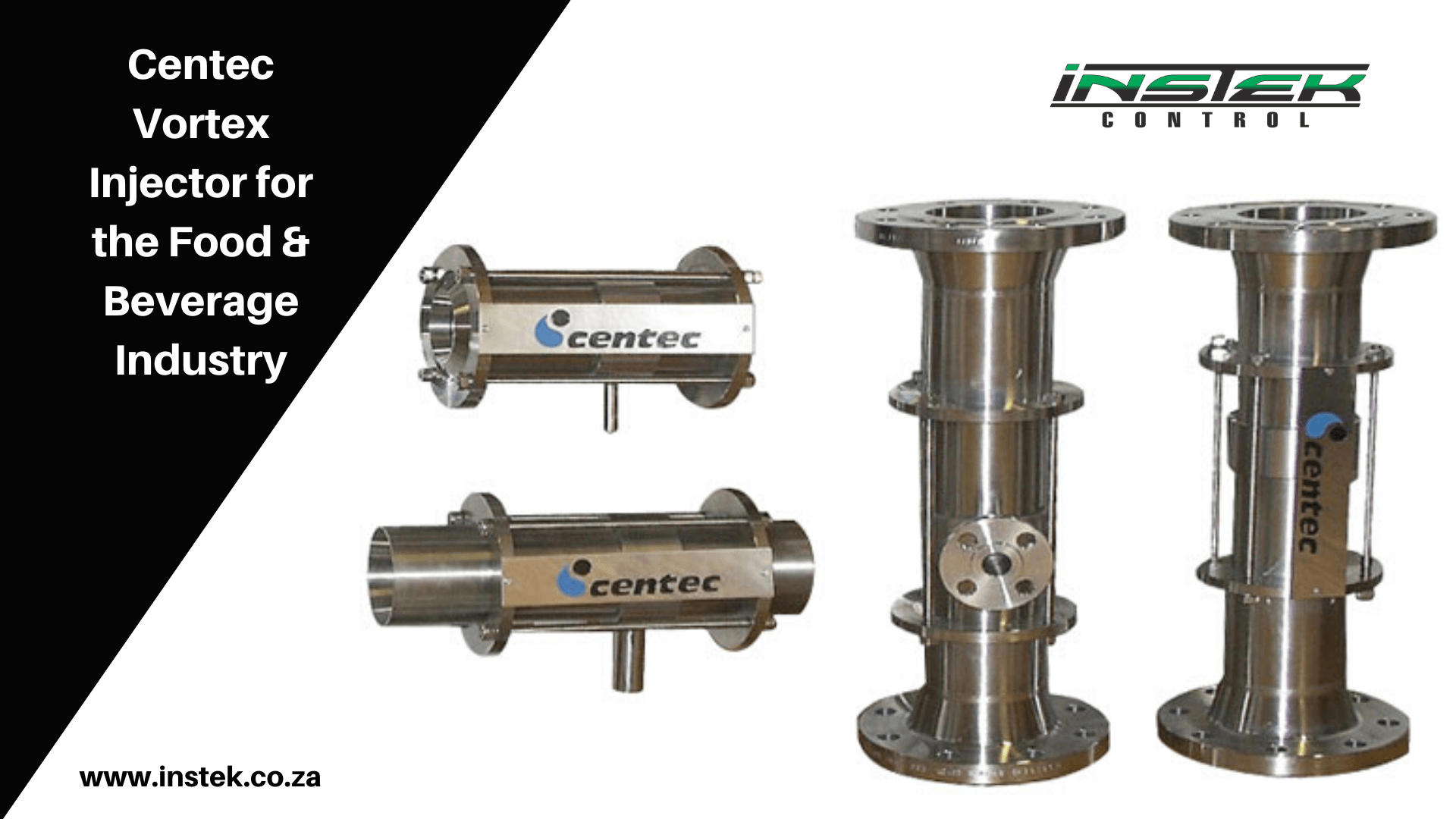

Centec offer fully automated, process systems and high precision measurement technology. This product range is nearly unique. Their systems and sensors are engineered to perfectly meet the most demanding requirements of the brewery, beverage, food and pharmaceutical industries.

With a team of experiencedengineers, they aim to create quantifiable added value for their customers by

increasing the efficiency of their processes. Centec and INSTEK CONTROL cc are your partners from planning and design through to commissioning of your plant.

AUTOMATED PROCESS UNITS

The broad range of Centec process units includes automated process skids designed to customer requirements for the following applications:

- Water Softening & Demineralization

- Reverse Osmosis

- Electrodeionization

- Ultra Filtration

- WFI Distillation

- Membrane De-Aeration

- Hot- or Cold Column De-Aeration

- Wort Aeration & Yeast Dosing

- Carbonation & De-carbonation

- Nitrogenation

- High Gravity Blending

- Multi Component Mixing

- Additive Dosing

- Product Sterile Filtration

- Flash Pasteurization

- Cleaning-in-Place (CIP)

- Sterilization-in-Place (SIP)

- Pure Steam Generation

- De-Alcoholization

- Vacuum De-Aration

SENSORS

Centec sensors are applied in laboratory and process environments as stand-alone devices or as part of a process control system.

- OXYTRANS Oxygen (O2) Measurement in Liquids and Gases

- CARBOTEC Dissolved Carbon Dioxide (CO2) in Liquids

- RHOTEC Online Concentration Measurement by Density

- RHOTEC L Concentration Measurement by Density for Laboratories

- SONATEC Concentration Measurement by Sound Velocity

- COMBITEC Density and Sound Velocity Measurement

For more information on the Centec product range contact Instek Control or visit the website.

021 998 632, info@instek.co.za , www.instek.co.za