Online Moisture Measuring Systems

Werne & Thiel moisture measuring sensors always represent the latest technology of well-proven HPRMethod (High Frequency Dielectric Polarisation and Field Refraction) and offer unique precision and reliability. For decades they are in touch with their customers to be able to always give them an innovative product perfectly fitting their needs.

Research and Development

• Since 40 years one of the leading manufacturers of online moisture measuring systems

• Innovation based own research - and development department

• Customer - specific solutions thanks to flexible and individual in - house assembly

• All sensors are developed and manufactured in Germany

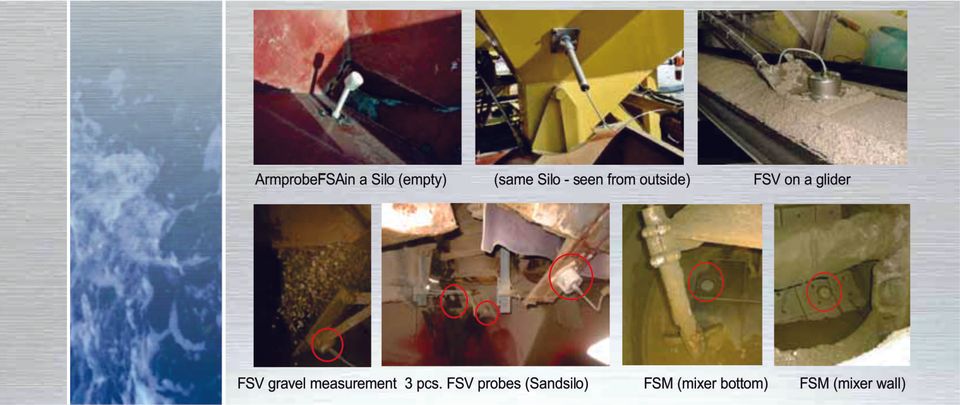

Sensors of the newest generation are available by different replaceable wear protections:

• Special-Ceramic

(extremely abrasion resistant)

• Wear resistant rubber

(abrasion resistant, impact proof)

Accuracy: 0.1% . . . 0.5% depending on installation situation and correct calibration

Easy calibration of the sensor by integrated adjustment unit.

Output Signal: 0-10 V or 0/4-20mA - no additional processing unit required

Operating voltage: 9-30V DC (also available +15V DC and -15V DC)

Specific appointment of moisture thanks internal digital linearization of the measuring signal

Samples of application area:

• Moisture content of sand, gravel, etc in concrete production

• Reprocessing of foundry sand for desired moisture content

• Moisture content of quartz sand e.g. for glass manufacture

• Quality optimizing in food processing

• Corn production

• Fodder industry for animal food

• Woodworking Industry (wood chips, sawdust, wood shavings, wood pellets production)

• Ceramic powders and pastes; metal oxides

• Sludge from the sewage plants

Contact Instek Control for more information or email info@instek.co.za