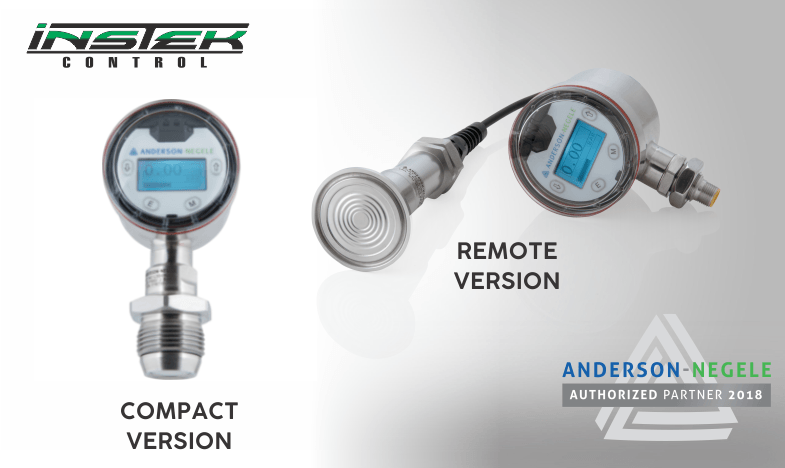

Pressure, hydrostatic level and volume sensor - L3

Instek Control • October 24, 2018

L3 MAJOR BENEFITS

» 4...20 mA with HART 7.0 and user configurable switching output

» Compact or Remote Version available and upgradable

» Turndown till 10:1 possible, till 5:1 without loss of measuring accuracy

» High accuracy and improved temperature compensation

» Smart display and easy-to-use menu

» Integrated tank linearization and density compensation

» Compact and remote version available

A compact model can be changed to remote easily with a retrofitting kit due to the modular design of components

A compact model can be changed to remote easily with a retrofitting kit due to the modular design of components

▪Difficult installation situation on tank bottom

▪Better visibility of the display

▪High vibrations of the system

» Turndown till 10:1

▪Example: If the stem is intended for 0...4 bar measuring range can be adjusted down to 0...0,4 bar

▪Advantage: Flexibility! One instrument can be used for different applications

»Accuracy

▪ Turndown to 5:1 < 0.10 % of calibrated range

▪ Turndown to 10:1 < 0,15 % of calibrated range

▪ Accuracy based on calibrated range. In the example above, accuracy would be better than 0,15 % of 0...0,4 bar

▪ This high accuracy makes the instrument suitable for level applications in small vessels.

»Temperature compensation

▪ Appx. 10 times better than DAN - HH

▪ Temperature influence: 0,003 % / °C of calibrated range

Example:

Calibrated range 0-10 bar

If temperature changes by 50°C - influence only appx. 15 mbar

Calibrated range 0-10 bar

If temperature changes by 50°C - influence only appx. 15 mbar

L3 is very good for applications with temperature changes

Examples:

•Small Buffer vessels

•Hot applications like in breweries

▪But: Consider the max process temperature of 110°C permanently (CIP/SIP 130°C for 60 min as usual)

» Display and easy-to-use menu

▪Easy and intuitive navigation

▪Only 4 buttons: Up/Down and Menu/Enter

▪Numerical display and bar graph

▪All parameters can be configured

▪Configuration via display or HART possible

▪Factory preset values can be modified

DOWNLOAD DATASHEET

Contact INSTEK CONTROL for more information info@instek.co.za

DOWNLOAD DATASHEET

Contact INSTEK CONTROL for more information info@instek.co.za

Digitalisation has already found its way into many branches of industry under the keywords "Industry 4.0" or "Internet of Things", and today it is impossible to imagine life without it. INSTEK Control is excited to announce that the new dimension in hygienic measuring technology is digital and analogue, compact or remote and modular.

When it comes to a brewery, you clean to prevent the transfer of tastes from one beer to the next, and you clean to help assure your product is safe for human consumption. In the face of increasing supply and demand, brewing plants are compelled to keep the cost of production as low as possible, without sacrificing safety and quality of the end-product.